- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

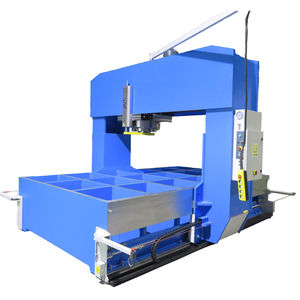

Hydraulic press line formingPLC-controlledcustom

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic

- Function

- forming

- Control

- PLC-controlled

- Other characteristics

- custom

- Applications

- process, for plastics

- Force

Max.: 685 kN

Min.: 0 kN

- Stroke

380 mm

(14.961 in)- Max. pressure

Max.: 180 bar

(2,611 psi)Min.: 0 bar

(0 psi)- Approaching speed

10 mm/s

Description

This custom-made press line is designed with 4 hydraulic workshop presses from Profi Press. Especially indicated to carry out the forming of plastic material.

This press line is equipped with supply rails, a heating section, a cooling section and a PLC-control to regulate the pressure, cycle-time and position of the piston. The material is placed in the heating section (the first two presses) where it will be heated and formed with a constant pressure during 40 minutes. After these 40 minutes, the material slides into the cooling section where the same process takes place with a low temperature.

Supply rails

A heating section

A cooling section

PLC control to regulate the pressure, cycle time and position of the piston

VIDEO

Catalogs

No catalogs are available for this product.

See all of RHTC BV‘s catalogsRelated Searches

- RHTC industrial press

- RHTC forming press

- RHTC hydraulic press

- Bender

- RHTC automatic press

- Tube bender

- Hydraulic bender

- RHTC joining press

- RHTC electric press

- RHTC vertical press

- RHTC punching press

- RHTC ram press

- Pneumatic press

- RHTC manual press

- RHTC cutting press

- Punching center

- RHTC stamping press

- RHTC process press

- Section bending machine

- RHTC frame press

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.