- Machine-tools

- Machining Center

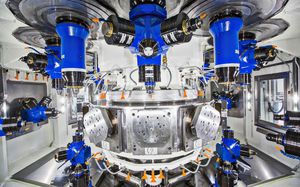

- Rotary transfer machine

- Riello Macchine Transfer

Rotary transfer machine VFX 600CNC4-position6-position

Add to favorites

Compare this product

Characteristics

- Type

- rotary

- Control type

- CNC

- Number of positions

- 4-position, 6-position, 8-position

- Other characteristics

- automated loading/unloading, 5-axis

Description

The Vertiflex 600 is a flexible manufacturing cell, natural evolution of VFX 300 and VFX 450 versions, with the additional possibility of mounting, on some dedicated stations, a pallet holding rotating fixtures - not only on the conventional B axis – but also on a second axis (A axis), so obtaining a full 5-axis interpolated positioning. The full CNC pallet rotators, including that one of the loading/unloading station, are moved by a Torque motor to 360.000 positions and hydraulically locked. The machining modules, up to a maximum of 8, are real machining centers moving on x, y, z axes.

The full CNC pallet rotators, including that one of the loading/unloading station, are moved by a Torque motor to 360.000 positions and hydraulically locked. The machining modules, up to a maximum of 8, are real machining centers moving on x, y, z axes. Each machining center is equipped with 6- or 8-position tool change revolver head and allows to suit up to 64 tools in the full configuration. 5-axis machining can be provided in one station for the 4-station VFX 600 and in two stations for the 6-station VFX 600.

TOOL MONITOR

Riello Tool Monitor works by monitoring the spindle motors absorption, through a direct reading inside the drives and thanks to an on-purpose developed SW. Management of pre-alarms levels and of missing tool alarms. Teach-in function. Possibility of selection via RUI interface.

BK MIKRO

Mechanical tool detecting system. Motorized head nearby the tool, equipped with detecting stick. Management of broken tool and of detector non-rotation alarms. Selection via RUI Interface.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Riello Macchine Transfer‘s catalogsOther Riello Macchine Transfer products

FLEXIBLE TRANSFER MACHINES

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- 3-axis CNC milling machine

- CNC machining center with pallet changer

- Horizontal CNC machining center

- Universal CNC machining center

- CNC transfer machine

- Rotary transfer machine

- CNC milling machine with pallet changer

- Multi-spindle CNC machining center

- Multi-spindle transfer machine

- Machining transfer machine

- 8 tools CNC machining center

- High-productivity transfer machine

- Turning transfer machine

- 4-position transfer machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.