- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Non-contact measuring system RF096-32/42-100 diametergeometriclaser

Add to favorites

Compare this product

Characteristics

- Measured physical value

- diameter, geometric

- Technology

- laser

- Measured material

- for inside diameter measurements

- Applications

- control

- Other characteristics

- non-contact

Description

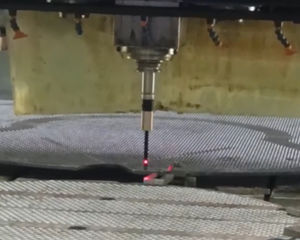

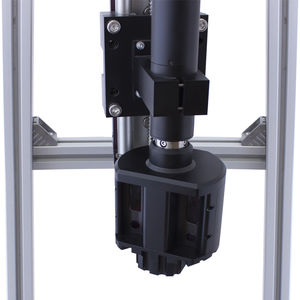

The machine is designed for contactless scanning and geometrical parameters measurement of inner diameter of pipes, bushes, holes, tubes, and so on. Application of the machine: large-scale production.

Operation of the machine is based on the principle of laser scanning of rotating pipe inner surface by triangulation laser point sensor. The controlled pipe is installed into the V-block. At the command from the operator, a laser sensor moves into the control zone of the pipe, and the V-block is driven to rotate. During rotation, a laser sensor measures the distance to the surface of the ring in synchronization with the angle of rotation determined by the encoder. Upon completion of one turn of the pipe, a laser sensor moves to the next control position, and the measurement process is repeated. The number of diameter control sections along the pipe is defined by the software. Radial coordinates of the pipe surface are transmitted to the computer for calculating the required geometric parameters (ID, ovality, roundness and so on).

Main features:

• - Measured ID range 32…42 mm

• - Measurement accuracy ±5 um

• - Inspections time ( five sections) 13 s

VIDEO

Catalogs

PRODUCT CATALOG 2024

40 Pages

Other RIFTEK EUROPE products

Laser Systems for Inner Diameter Measurement

Related Searches

- Measuring device

- Measuring machine

- Digital measuring device

- Micrometer

- Optical measuring machine

- Automatic measuring machine

- Laser scanning system

- Measurement scanning system

- 3D scanning system

- High-precision measuring machine

- Measuring system for industrial applications

- Parts measuring machine

- Compact measuring device

- Distance measuring machine

- Control measuring machine

- Non-contact measuring machine

- Digital micrometer

- Laser measurement system

- Diameter measuring machine

- Video measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.