- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Diameter measurement system lasertube

Add to favorites

Compare this product

Characteristics

- Measured physical value

- diameter

- Technology

- laser

- Measured material

- tube

Description

The operation of the system is based on the principle of scanning the inner surface of holes with a rotating laser triangulation sensor.

Main components of the system:

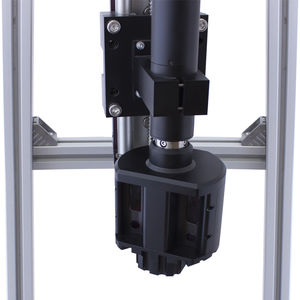

• Laser triangulation probe(s) RF609-Wi-Fi Series;

• Industrial tablet with software.

Hole inspection is performed as follows:

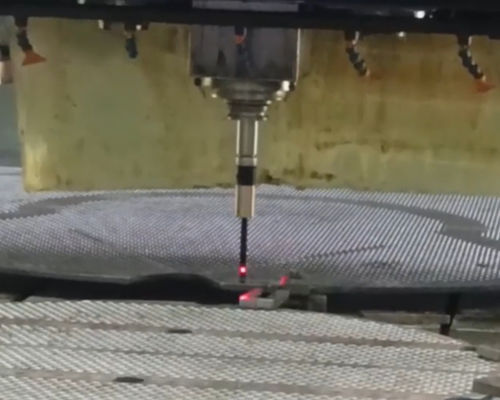

• The laser triangulation probe is installed in the spindle of the CNC machine.

• The CAD file of the controlled tube sheet is uploaded into the program on the tablet.

• The operator enters the spindle rotation speed, the probe feed rate and the sequence of measuring the tube sheet holes into the machine program and the system program.

• The tablet is switched to data reception mode, and the scanning program is launched on the machine.

During the measurement process, the machine sequentially, in accordance with the selected algorithm, inserts a rotating laser probe into the controlled hole. The laser probe transmits measurement data to the tablet, and the tablet software calculates the geometric parameters of each hole and displays them in a graphic color code. After completing the measurements, the operator generates a report.

VIDEO

Catalogs

No catalogs are available for this product.

See all of RIFTEK EUROPE‘s catalogsOther RIFTEK EUROPE products

Laser Systems for Inner Diameter Measurement

Related Searches

- Measuring device

- Measuring machine

- Digital measuring device

- Micrometer

- Optical measuring machine

- Automatic measuring machine

- Laser scanning system

- Measurement scanning system

- 3D scanning system

- High-precision measuring machine

- Measuring system for industrial applications

- Parts measuring machine

- Compact measuring device

- Distance measuring machine

- Control measuring machine

- Non-contact measuring machine

- Digital micrometer

- Laser measurement system

- Diameter measuring machine

- Video measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.