- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

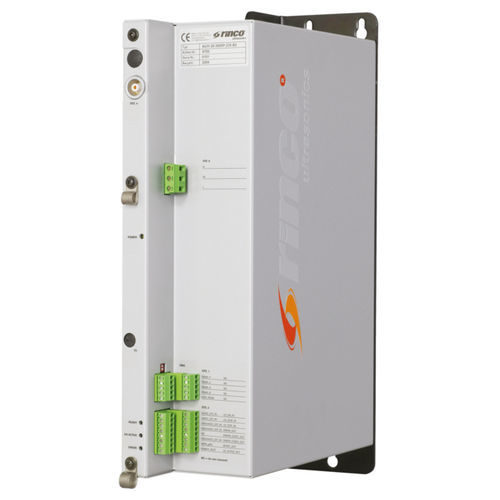

Plastics welding ultrasonic generator AGM series

Add to favorites

Compare this product

Characteristics

- Applications

- for plastics welding

- Ultrasonic frequency

20 kHz, 30 kHz, 35 kHz, 40 kHz, 70 kHz

- Rated power

Min.: 100 W

(0.14 hp)Max.: 3,000 W

(4.08 hp)

Description

Generators from the AGM series are designed for installation in automated lines and special purpose machines to control ultrasonic actuators and components. Thanks to their slim design, they can be incorporated into small spaces in electrical cabinets.

Applications are available for both generators for entering parameters simply and conveniently via a terminal device and for exporting and analysing data.

AGM-series generators are compatible with all special actuators and the CH35-4 cutting head.

The generator communicates with the PLC via digital I/O, RS485 or CANopen.

Thanks to the welding modes, you can find the right setting for every application, meaning that perfect welding is guaranteed. The following welding modes can be selected on the AGM series:

- Time mode

- Energy mode

- Welding time AND/OR welding energy

- Continuous mode

The AGM ultrasonic generators can be used to set a wide range of limits that issue a warning or stop the welding process.

RINCO generators operate very reliably and have a long service life.

A part counter and a reject counter are integrated into all ultrasonic generators from the AGM series.

Multi-level user administration.

With the application which we developed internally, it is possible to set parameters and save parameter datasets via a PC/laptop. During the welding process, the current values are displayed as a diagram and are therefore immediately ready to be analysed. The welding data can also be exported for traceability purposes. You can easily update the software via USB.

Errors can be split into the following groups: generator, oscillator system and limits.

VIDEO

Catalogs

AGM Series

2 Pages

Other RINCO ULTRASONICS AG products

ULTRASONIC GENERATORS AND MODULES

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.