- Power Transmission - Mechanical components

- Mechanical Transmission

- Torsionally flexible coupling

- RINGFEDER POWER TRANSMISSION GMBH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

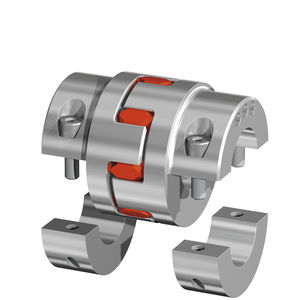

Elastomer coupling TNM Gjawtorsionally flexibleclaw

Add to favorites

Compare this product

Characteristics

- Type

- elastomer, jaw, torsionally flexible, claw

- Product applications

- shaft, machines

- Other characteristics

- torque

- Installation system

- flange

- Torque

Min.: 48 Nm

(35.403 ft.lb)Max.: 41,000 Nm

(30,240.0481 ft.lb)- Rotational speed

Min.: 1,200 rpm

(7,539.82 rad.min-1)Max.: 5,000 rpm

(31,415.93 rad.min-1)

Description

Three-part design, elastic ring can be replaced without having to axially move the machine

The coupling RINGFEDER® TNM G is a torsionally elastic and puncture-proof claw coupling. It balances out angular, radial, and axial shaft misalignments within defined limits. The coupling transfers the torque via pressure loadable, elastic buffers of synthetic rubber (Pb) which are joined together as an intermediate ring. The elastic intermediate ring can cushion impacts and torsional vibrations; it is oil-resistant and electrically conductive. A coupling half is divided in two and allows through this a simple separation of the coupled machine. With the claw ring pulled back it is possible to check the rotational direction of the drive. It is also possible to lift out radially a coupling half with accompanying aggregate. The elastic intermediate ring can be changed without axially shifting the machine. The coupling is usable in every sense of rotation and installation position.

INTRODUCTION

The rotationally resilient coupling of the RINGFEDER® TNM series is flexible in all directions and therefore compensates for angular, parallel and axial shaft misalignments of the connected machines. Misalignments can be caused, for example, by inaccurate assembly, heat movements or settling phenomena.

Avoiding Torsional Vibration

By virtue of the rotational resilience of the coupling, dangerous torsional vibrations from the operational range of plant machinery can be transferred to rotational speed ranges in which no negative effects are to be expected.

Catalogs

Other RINGFEDER POWER TRANSMISSION GMBH products

Elastomer Jaw Couplings

Related Searches

- Clamp

- Flexible shaft coupling

- Shafts coupling

- Flange shaft coupling

- Torque shaft coupling

- Rigid shaft coupling

- Backlash-free coupling

- Transmission shaft coupling

- Workholding component

- Sleeve shaft coupling

- Compact shaft coupling

- High-torque shaft coupling

- Disc shaft coupling

- Mechanical workholding component

- Industrial shaft coupling

- Gear coupling

- Maintenance-free shaft coupling

- Elastomer shaft coupling

- Jaw shaft coupling

- Machines coupling

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.