- Products

- Catalogs

- News & Trends

- Exhibitions

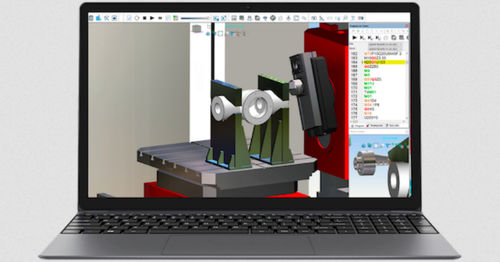

Management software G-codeinterfacesimulationprogramming

Add to favorites

Compare this product

Characteristics

- Function

- management, interface, simulation, programming, CAD, optimization, CAM

- Applications

- process, for machine tools

- Type

- 3D

Description

Eureka performs a complete 3D-simulation of machine tools through a simple and intuitive graphical interface, starting from the G-code.

Verify the ISO programs of the machine considering macros, subroutines and cycles

The majority of CAM programs simulations do not consider macros, subroutines and cycles. The CAM simulation doesn’t consider the “machine zero", axis strokes, or the management of multi-heads and do not manage multi-heads, machines with more than 5-axes and also probing routines.

Eureka G-Code simulates the actual G-code regardless of how it was created, either manually, or post processed from a CAM Program. Eureka performs simulation based on a highly accurate and reliable “digital twin” of the machine tool and CNC controller.

Find the best set-up without taking the real machine out of production

The setup of machines and prove out of G-code programs can be a very long and costly process with a negative impact on production times, time-to-market and profitability.

With Eureka G-Code you can reduce machine setup time by up to 80%. In Eureka you can simulate and verify all ISO programs created either manually or post-processed from a CAM system.

Avoid the risk of collision, damage and downtime caused by programming errors

Programming errors are often the cause of collisions and damage. The result is wasted programming hours, damage of expensive workpieces, tools breaking and collisions with machine parts such as the spindle.

Thanks to the perfect digital replica of Eureka G-Code you can check and simulate your ISO programs comfortably seated at your PC and avoid costly programming errors that cause collisions and wasted time.

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.