- Machine-tools

- Machine Tool Accessory

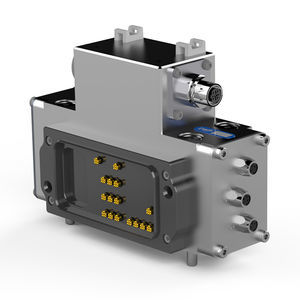

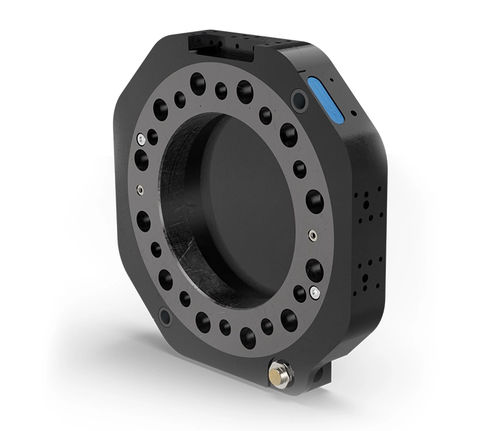

- Robotic tool changer

- Robot System Products AB

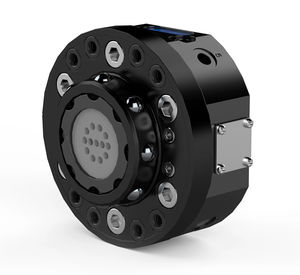

Robotic tool changer TA960-1automatic

Add to favorites

Compare this product

Characteristics

- Applications

- robotic

- Type

- automatic

Description

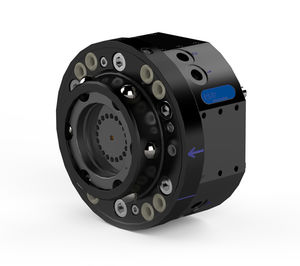

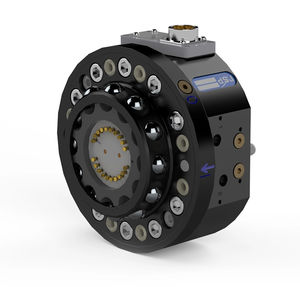

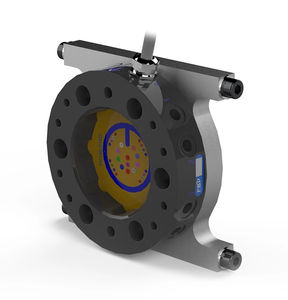

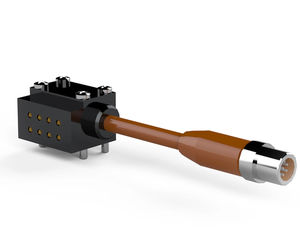

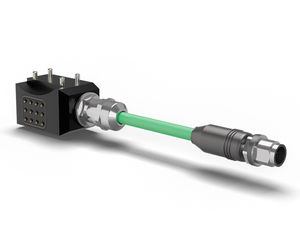

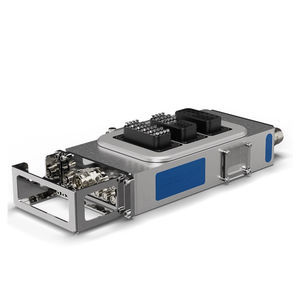

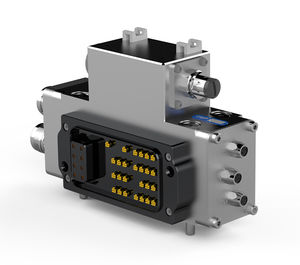

Modular design

External signals

Wide range of media modules – simple to customize

Designed to meet bodyshop application demands

Tool changing ability

The RSP tool changers are designed to maximize the flexibility and reliability of your robot fleet. They offer the possibility to enhance your robot application by allowing it to switch between different tools, such as grippers, weld units, fixtures etc. Tool changers from RSP are robust and can manage continuous changing operations with maintained reliability and safety. Depending on model and options, electrical signals, weld and servo power, data, water, and compressed air can be transferred from the robot side to the tool.

Mechanical interface -

ISO 9409-1 265-12-M16, ISO 9409-1 250-10-M12

Robot payload -

1200 kg | 2600 lb

Fz -

± 15000 N | ± 3300 lb

Mz -

± 10000 Nm | ± 88000 lbf·in (M14), ± 12500 Nm | ± 110600 lbf·in (M16), ± 6000Nm | ± 53000 lbf·in (M10 screw class 12.9), ± 9000Nm | ± 79700 lbf·in (M12 screw class 12.9)

Mx/My -

± 10000 Nm | ± 88000 lbf·in (M12 screw class 12.9), ± 15000 Nm | ± 132700 lbf·in (M14), ± 15000 Nm | ± 132700 lbf·in (M16), ± 7000 Nm | ± 62000 lbf·in (M10 screw class 12.9)

Weight -

15.9 kg | 36.06 lb

Height -

50 mm | 1.97 in

Air channels available to tool -

1, Additional channels can be added with external media module

Air connection, outlet -

G 1/2"

Air flow per channel -

2000 l/min | 70.6 CFM

Max air pressure -

10 bar | 145 psi

Air quality -

Oil-clean and waterless filtered air, with max 25µm particle content

IP Class -

IP 54

Working temperature -

+10°C – +50°C | 50 °F – 120 °F

Catalogs

No catalogs are available for this product.

See all of Robot System Products AB‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.