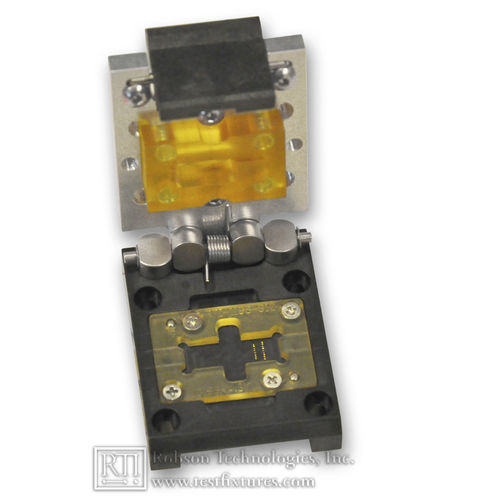

Reliable compression mount burn-in and HAST test sockets are a high-performance, low-cost, and semi-custom alternative to injection molded burn in sockets. Designed with a clamshell lid with z-axis pressure plate allows for tolerances of package thickness. Test sockets can be tailored to electrical and environmental test requirements.

Features:

Temperatures from -55C to + 150C

Contact force: 25-40gms

Long lifespan and insertions

High current options available

High-performance plastics and aluminum

Small footprint to maximize sockets per board

Fast standard turnaround, expedites available