- Power Transmission - Mechanical components

- Mechanical Transmission

- Clamping

- ROEMHELD NORTH AMERICA

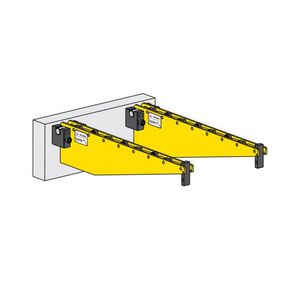

Manually-controlled clamp B1.8491workpieceswingdouble-acting

Add to favorites

Compare this product

Characteristics

- Type

- manually-controlled

- Applications

- workpiece

- Other characteristics

- swing, double-acting, compact, single-acting, cam, small

- Clamping force

2.6 kN

Description

Single or double acting

available in one clamp size

single or double-acting

standard fittings or manifold mounted, with a choice of clockwise, counterclockwise, or zero° swing.

available with 45° and 60° swing angles by special order.

clamping force at 5000 psi forSwing Clamps utilize a sturdy helical-cam mechanism to swing the clamping arm clear for unrestricted loading. The Compact Swing Clamps shown here are extremely small, economical clamps suitable for many applications. Clamping arm can be mounted to start its 90° swing from any position within 360°. The flange-base version provides many plumbing options, including manifold mounting.

Available in one clamp size, single acting (shown here) or double-acting (see Related Products below), standard fittings or manifold mounted, with a choice of clockwise, counterclockwise, or zero° swing. Available with 45° and 60° swing angles by special order. Clamping force at 5000 psi for single-acting clamps with a standard arm: 450 lbs (1 series)

Design Considersation

Due to their small size, these Swing Clamps do not have overload protection; therefore the swing motion must not be restricted in any way. Be sure to adjust the contact bolt so that the clamp completes its full swing stroke and starts its clamping stroke before contacting the workpiece. To be safe, use low operating pressure during initial setup.

Do not exceed maximum fluid flow rate in table. For extended clamp life a simple flow-control valve may be required if the fixture is powered by a high-flow-rate power source and only contains a few clamps. Clamping time should be at least one second.

Clamping Arm

VIDEO

Catalogs

B 1.849 Compact Swing Clamps

4 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.