- Hydraulics - Pneumatics

- Pipe, Tube and Fitting

- Hydraulic fitting

- ROEMHELD NORTH AMERICA

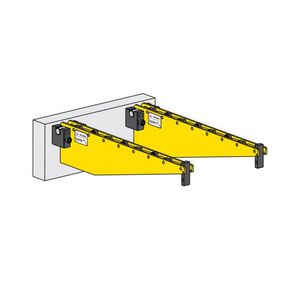

Hydraulic fitting F9.428threadedtransfer

Add to favorites

Compare this product

Characteristics

- Applications

- hydraulic

- Attachment

- threaded

- Other characteristics

- transfer

- Diameter

3 mm, 5 mm, 8 mm, 12 mm

(0.118 in, 0.197 in, 0.315 in, 0.472 in)- Operating pressure

500 bar

(7,251.89 psi)

Description

threaded-body type, max operating pressure 500 bar

transfer hydraulic oil or compressed air from the machine table to the hydraulic clamping fixture

4 different nominal diameters for optimum adaptation to the flow rate

built-in and threaded-body type of the same nominal size can be combined

axial sealing disk easily renewable

additional bushing simplifies the fabrication of the location hole for the coupling mechanism

relatively large positioning tolerances

On machine centers with pallet changing systems, the coupling elements transfer hydraulic oil or compressed air from the machine table to the hydraulic clamping fixture. The coupling mechanism and the coupling nipple is provided with axial seals (see coupling situation) and have a very short coupling stroke. The smooth front face of the coupling mechanism is easy to clean in case of swarf formation. The recessed sealing disk can be easily replaced with the assembly tool if it is damaged. The built-in type is fixed with an intermediate plate and is particularly suitable for multi-couplings.

Catalogs

No catalogs are available for this product.

See all of ROEMHELD NORTH AMERICA‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.