- Packing - Handling - Logistics

- Conveying

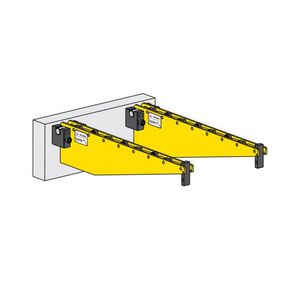

- Slip-on conveyor roller

- ROEMHELD NORTH AMERICA

Slip-on conveyor roller 8.1834Aaluminum alloyfor heavy loads

Add to favorites

Compare this product

Characteristics

- Drive mechanism

- slip-on

- Material

- aluminum alloy

- Other characteristics

- for heavy loads

- Max. load capacity

6 kN, 8 kN

Description

For heavy loads, hydraulic lifting of the complete bar

fits in T-slots and rectangular slots of press beds for easy die change

die change streamlining

For heavy loads, for linear movement of dies: On the underside of the roller bar lifting pistons are provided. Pressure is applied to these pistons using hydraulic pressure generators, which lift then the complete roller bar. The die positioned on the roller bars is not in contact with the table top and can be easily moved and positioned. The basic bodies are made from a high-strength and robust aluminium alloy. Max. operating pressure: 400 bar Load-bearing capacity: up to 160 kN/m, roller spacing 50 mm. Any length up to 2500 mm is possible using modular segments. Fastening of the roller bar using a fastening plate.

Catalogs

No catalogs are available for this product.

See all of ROEMHELD NORTH AMERICA‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.