- Products

- ROFA Group

- Products

- Catalogs

- News & Trends

- Exhibitions

Transportation equipment for tracked equipment

Add to favorites

Compare this product

Description

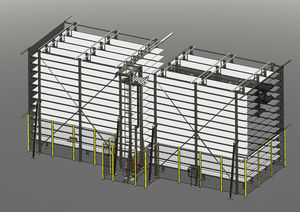

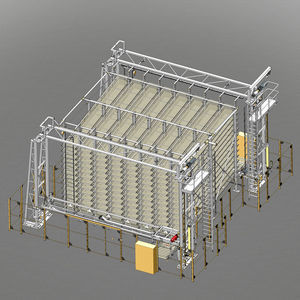

The new generation of rail guided transport systems

The special feature of this system is that the wheels rest with two points on the “Gothic arch” on a round rail. The contact angle equates to about 30°. Because of this, and compared to conventional crane gantries or rail tracks, power transmission is significantly increased, resulting in the ability to transport larger payloads. The combination of round track and running wheels also produces reduced friction. This minimizes the force required for movement and also the wear on the drive.

Heavy duty transportation characteristics:

Up to 70 ton load capacity

Conversion of the assembly process from insular to linear flow

Continuous assembly with automated flow or time controlled movements

The time interval can be adjusted to suit different production processes

Good flexibility to add-on to the system (for example to increase the production capacity)

Possibility to transport workers on the mounting platforms

Coupling with other (higher) systems is possible (e.g. Andon, Visualizing, MFR, etc.)

Maximum flexibility in the design of the layout

The rails can be driven over or fixed flush to the floor (e.g. to allow forklifts to cross)

using additional power transmission, extra functions are possible at any time (e.g. supply of lifting units, ride-on test, or control units)

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.