- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

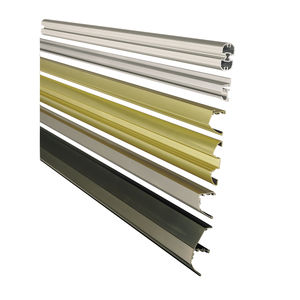

Electrolytic chrome plating harddecorativesteel

Add to favorites

Compare this product

Characteristics

- Type

- electrolytic, hard, decorative

- Substrate

- steel, aluminum, zinc, nickel, copper

- Applications

- for industrial applications, for agricultural applications

- Production method

- large series, small series, medium series, prototyping, individual

Description

Pearl-brightness chromium plating

The term is misleading because to be technically correct this process involves nickel plating with pearl-brightness (satin finish) and subsequent chromium plating. Items treated in this way acquire a very attractive appearance, whereby to a large extent small surface defects in the material become "invisible”.

Applications for this process are found e.g. in the furniture industry and a lot of technical areas where this is needed for design reasons or a non-dazzling effect is required.

Depending on requirements, a typical layer structure consists of approx. 10-30 µm pearl-brightness nickel and approx. 0.3-0.5 µm chromium. Nowadays, the copper undercoating which used to be customary (with subsequent mechanical polishing to acquire brightness) is dispensed with by and large because modern high-power baths are able to produce a sufficient degree of levelling and brightness, and copper with the same overall thickness does not increase resistance to corrosion.

Catalogs

No catalogs are available for this product.

See all of Rohde AG‘s catalogsRelated Searches

- Rohde anodizing

- Rohde aluminum anodizing

- Rohde anodizing with coloring

- Nickel plating

- Electroless nickel plating

- Rohde small series anodizing

- Rohde large series anodizing

- Rohde medium series anodizing

- Rohde hard anodizing

- Zinc-plating

- Galvanizing

- Hot dip galvanizing

- Rohde medical anodizing

- Chrome plating

- Rohde industrial anodizing

- Rohde titanium anodizing

- Steel nickel plating

- Rohde individual anodizing

- Aluminum nickel plating

- Steel galvanizing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.