- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

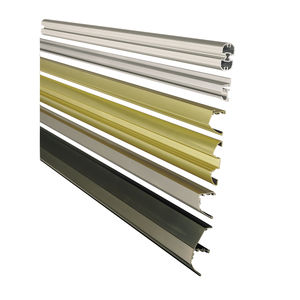

Chrome plating

Add to favorites

Compare this product

Description

High-gloss chromium plating

To be technically correct, this process – as is the case with pearl-brightness chromium plating – involves high-gloss nickel plating and subsequent chromium plating. A typical layer structure here also consists, depending on the requirement, of approx. 10-30 µm nickel and approx. 0.3-0.5 µm chromium. As regards copper undercoating, the same applies as in pearl-brightness chromium plating.

For decorative high-gloss chromium plating the basic material must either be smooth and faultless or the items to be chromium-plated must be mechanically treated first by grinding, brushing and/or polishing. Special attention must be paid here as these operations are usually very cost-intensive and sometimes more than double the chromium-plating price.

The other side of this page shows the brazed arm holders used in the group of table and chairs in the photo above them; to attain a perfect surface, these are ground in vibratory grinders for about 3 hours and only then plated with high-gloss chromium.

Catalogs

No catalogs are available for this product.

See all of Rohde AG‘s catalogsRelated Searches

- Rohde anodizing

- Rohde aluminum anodizing

- Rohde anodizing with coloring

- Nickel plating

- Electroless nickel plating

- Rohde large series anodizing

- Rohde small series anodizing

- Rohde medium series anodizing

- Zinc-plating

- Rohde hard anodizing

- Galvanizing

- Hot dip galvanizing

- Rohde industrial anodizing

- Rohde medical anodizing

- Chrome plating

- Steel nickel plating

- Rohde titanium anodizing

- Aluminum nickel plating

- Rohde individual anodizing

- Steel galvanizing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.