- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

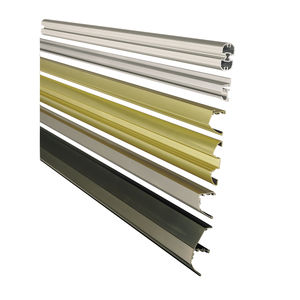

Hard anodizing sulfuricchromicaluminum

Add to favorites

Compare this product

Characteristics

- Type

- hard, sulfuric, chromic

- Type of substrate

- aluminum, titanium

- Applications

- industrial, medical, for the construction industry, for the food industry, for robotics

- Production method

- large series, small series, individual

- Other characteristics

- with coloring

Description

Components for Laboratory Centrifuges

Components of this kind in a wide variety of versions rank among the most precise and expensive individual parts in a centrifuge.

The extreme accelerating forces, which develop at high rotational speeds – along with the material deformation this causes – makes demands accordingly on the quality of the anodized finish. Compliance with certain bath parameters is extremely important therefore for the quality of the anodized layer. To increase resistance to corrosion and UV radiation, the articles illustrated here are also sealed in a nickel-acetate solution.

It is not always possible to give high-strength wrought aluminium alloys with different contents of copper, zinc, manganese and other metals a decorative anodized finish, because some alloying additions, even in small quantities, produce inherent colours, which can cause characteristic structures, where there are textural irregularities (see under "Brief Specialist Information”).

Catalogs

No catalogs are available for this product.

See all of Rohde AG‘s catalogsRelated Searches

- Rohde anodizing

- Rohde aluminum anodizing

- Rohde anodizing with coloring

- Nickel plating

- Electroless nickel plating

- Rohde large series anodizing

- Rohde small series anodizing

- Rohde medium series anodizing

- Zinc-plating

- Rohde hard anodizing

- Galvanizing

- Hot dip galvanizing

- Rohde industrial anodizing

- Rohde medical anodizing

- Chrome plating

- Steel nickel plating

- Rohde titanium anodizing

- Aluminum nickel plating

- Rohde individual anodizing

- Steel galvanizing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.