- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

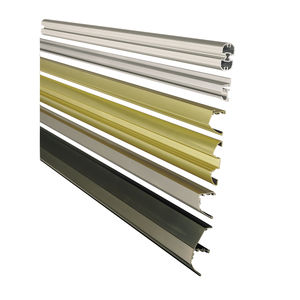

Hard anodizing aluminumtitaniumindustrial

Add to favorites

Compare this product

Characteristics

- Type

- hard

- Type of substrate

- aluminum, titanium

- Applications

- industrial, for the aerospace industry, medical, for the construction industry, for the food industry, for robotics

- Production method

- medium series, large series, small series, individual

- Other characteristics

- with coloring

Description

Hard-Coat

Contrary to the standard anodizing process the protective layers, the protective layers obtainable with hard-coating are considerably harder and thicker – comparable to hard chrome layers – and hence they are preferably used for parts where it is specified by their technical application. Hard-coated layers possess a self-colouring capacity depending on the alloy and the layer thickness. Moreover, their porosity (absorbency of colourings) is significantly lower than with the regular anodizing procedure so that the possibility of the additional colouring is heavily reduced and limited to dark colour tones.

Hard-anodized layers possess no levelling effect, too, so that pits, scratches and damages will be visible after anodizing – therefore, as a rule, likewise a mechanical and/or chemical surface treatment is applied before, in order to eliminate such faults if high optical requirements are demanded. Both pre-treatment procedures involve material removal, though. Previously invisible inhomogeneities of the alloys also appear beyond the anodizing process and may cause optically disturbing structures.

Characteristics of Hard-Coating

- Hardness: 300 to 450 HV

- Layer thickness: up to 140 µm

- Material self-colouring capacity

- Wear-resistant – similar to hard-chrome

- Corrosion resistant against climatic influences and a multitude of chemicals

Catalogs

No catalogs are available for this product.

See all of Rohde AG‘s catalogsRelated Searches

- Rohde anodizing

- Rohde aluminum anodizing

- Rohde anodizing with coloring

- Nickel plating

- Electroless nickel plating

- Rohde small series anodizing

- Rohde large series anodizing

- Rohde medium series anodizing

- Rohde hard anodizing

- Zinc-plating

- Galvanizing

- Hot dip galvanizing

- Rohde medical anodizing

- Chrome plating

- Rohde industrial anodizing

- Rohde titanium anodizing

- Steel nickel plating

- Rohde individual anodizing

- Aluminum nickel plating

- Steel galvanizing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.