- Detection - Measurement

- Position, Speed and Acceleration Measurements

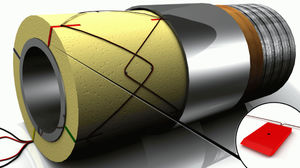

- Corrosion detector

- Rohrback Cosasco Systems

Corrosion detector inspection

Add to favorites

Compare this product

Characteristics

- Detected entity

- corrosion

- Application

- inspection

Description

The Insulated Braid Wire Sensor (patent pending) is designed to detect corrosion that has occurred over a relatively large area. A single insulated carbon steel wire of a certain element thickness, or multiple wires of varying thickness, eg 5 mil, 10 mil, 15 mil, and 20 mil thick wires, may be installed.

The time between the first wire corroding and the second (thicker) wire, and so on can be used to estimate the approximate rate at which the pipe surface is corroding. If installed under a tape coating, it can help determine the integrity of the coating and the corrosion on the pipe surface that may occur due to the coating breakdown.

Applied to surface of pipe as a continuous spiral or wire loop

Single or multiple, continuous wire detects corrosion over a relatively large area of cover

Multiple wire thickness option for determining corrosion rate

Low Cost , easy to install and interrogate

Applied on new pipelines, field joints, insulated process lines, installed after a repair

Potential Savings in inspection and associated repair costs

Requires removal of insulation

Catalogs

No catalogs are available for this product.

See all of Rohrback Cosasco Systems‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.