- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Thickness measuring system LTM-BASElaserfor metal bandsnon-contact

Add to favorites

Compare this product

Characteristics

- Measured physical value

- thickness

- Technology

- laser

- Measured material

- for metal bands

- Other characteristics

- non-contact

Description

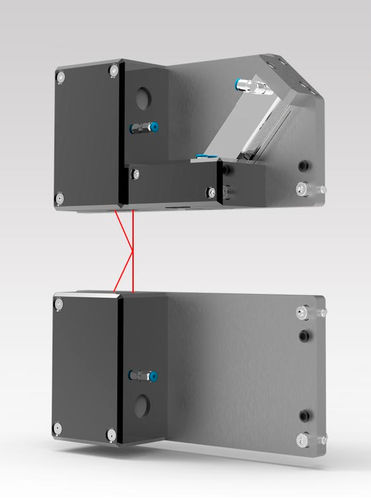

Non-Contact Thickness Gauging System for metal stripes with two triangulation lasers. Laser based function principle.

Up to 5 measuring tracks representable via controller.

Application

The LTM BASE has been designed for fast moving of steel/metal strips, especially for stamping presses or strip processing lines. Due to the high sampling rate up to over 50 kHz, the system is also used at the flexible roll forming of Tailored Rolled Blanks, as well as for punching, roll profiling and tube manufacturing.

Features

● Precision sensors with wide measuring point

● Fully automated calibration routine

● High precision laser thickness measurement in a compact system

● Extensive Software tools for measurement data aquisition and visualization

● Resolution of sensors 0.05 μm, measuring frequency up to 50 kHz

● Wide measuring spot especially for metalic surfaces

● Sensor - protection class IP 67, designed for rough environments

● Suited for the exchange of existing tactile systems

Technical Data

Application:

Fast moving of steel/metal strips, especially designed for stamping presses or strip processing lines

Material:

Steel / metal strips

Measuring area:

20 ± 10 mm

Resolution:

0.1 µm

Measuring principle:

Non-Contact Thickness Gauging, laser based function principle

Function principle:

Laser triangulation, Laser class2 (DIN / IEC), max. 0.95 mW

Sampling rate (adjustable):

20/50/100/200/500/1000 µs

Special features:

Up to 5 measuring tracks representable via controller

Precision sensors with wide measuring point

Fully automated calibration routine

VIDEO

Catalogs

Thickness Gauging

38 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.