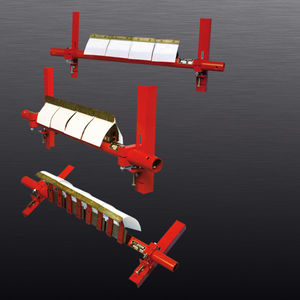

Slip-on conveyor roller steelabrasion-resistant rubberfor belt conveyors

Add to favorites

Compare this product

Characteristics

- Drive mechanism

- slip-on

- Material

- steel, abrasion-resistant rubber

- Other characteristics

- for belt conveyors

- Diameter

60 mm, 89 mm

(2 in, 4 in)- Length

200 mm

(7.9 in)

Description

Sticky transported material accumulates on regular roller sleeves and causes strong belt banking. Molded rubber disc rolls placed on the rollers prevent this from happening. With complex systems, it is often necessary to give more support to belt edges. This can be done by adding a molded disc rolls at each end. The non-abrasive molded rubber disc rolls are flush fitted to the roller and kept in position by steel spacers fixed at the ends with stop rings. Rollers with molded disc rolls positioned at specific distances can be supplied on request.

Catalogs

No catalogs are available for this product.

See all of roll-ven spa‘s catalogsRelated Searches

- Conveyor roller

- Metal conveyor roller

- Slip-on conveyor roller

- Steel conveyor roller

- Stainless steel conveyor roller

- Plastic conveyor roller

- Motorized roller

- PVC-coated conveyor roller

- Heavy load conveyor roller

- Driven conveyor roller

- Chain drive conveyor roller

- Galvanised steel conveyor roller

- Aluminum conveyor roller

- Conveyor belt cleaner

- Driven drum motor

- Thermoplastic conveyor roller

- Belt conveyor motorized roller

- Abrasion-resistant conveyor roller

- Rubber conveyor roller

- Conical conveyor roller

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.