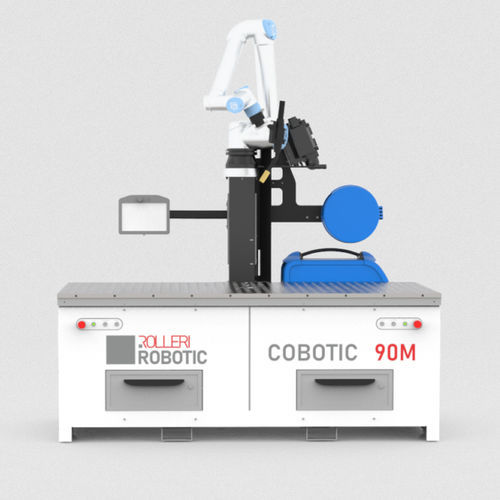

MIG welding robotic cell COBOTIC 90Mcuttingcollaborative

Add to favorites

Compare this product

Characteristics

- Function

- cutting, MIG welding

- Other characteristics

- collaborative

Description

MIG welding – wire welding with robotic cell COBOTIC 100M.

Programming on platform.

With COBOTIC 90M programming activity is extremely easy and suitable for small production batches too. The

remarkable software developments allowed to simplify all programming activities with significant reduction of programming

time.

The COBOTIC 90M unit has the extraordinary ability to integrate perfectly with the software for controlling the oscillations of the torch and managing the welding wire.

SIMPLE USE

Operations are quick and easy thanks to the most important commands being positioned on the torch handle. By using these commands, you can indicate the starting and finishing point or point at the sheet metal.

sistema intelligente - saldatura mig

SHAPE-DETECTING SYSTEM

By setting a starting and finishing point, can move autonomously and detect sheet metal deformation without any programming activity by the operator.

PRECISION +/- 0.1 mm

Cutting-edge technology thanks to the use of UR10e collaborative robot with 6 axes and 6 rotating DoF joints with +/-0.1mm precision and payload according to ISO 9283.

The machine control interface it’s really simple, buttons of program starting and stopping are really clear.

The touch screen control panel for programming and controlling the entire unit completes the equipment of COBOTIC 90M.

It is possible to set the starting point and the end point of the path but also to point the sheet metal through an extremely intuitive and fast command.

COBOTIC 90M structure has been designed for easy handling by forklift or crane, as it is composed of a unique part easy to be moved.

Catalogs

RR catalogo

32 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.