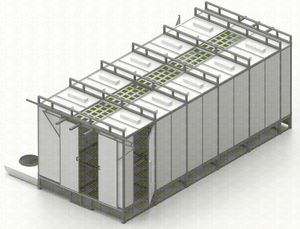

Enclosed powder coating booth automatic

Add to favorites

Compare this product

Characteristics

- Structure

- enclosed

- Other characteristics

- automatic

Description

Use of one photocell

The use of one photocell in the detail space allows you to measure its length, and thus, it gives you the option of switching on the guns when the detail appears in their range, and turning off the guns immediately after painting the detail. Photocell included as standard equipment.

Identification of details using special tags.

Plates with identification holes are placed over the detail sling.

n based on them, the PLC controller in conjunction with the photocell recognizes the painted detail, turns the guns on and off at the right time - thus saving energy and powder paint.

Vertical detail shape detection.

The use of light gates with horizontal detectors allows the PLC controller to analyze the detail shape vertically.

The PLC controller counts the time in which the detail should appear in the gun space - thanks to this, it is possible to selectively switch the guns on or off.

The use of light gates with multiple sensors horizontally and vertically.

This solution allows for precise measurement of detail dimensions, thanks to which it is also possible to control manipulators.

Benefits of gates and photocells

The benefits of using photocells or light gates are primarily powder and energy saving.

Elimination of painting the zone in which there is no detail.

Precise gun control when using light gates.

VIDEO

Catalogs

No catalogs are available for this product.

See all of ROMER P.P.‘s catalogsRelated Searches

- Automatic washing machine

- Water washing machine

- Industrial washing machine

- Ultrasonic cleaning system

- Spray gun

- Spray washing machine

- Paint gun

- Sprayer

- Spray booth

- Automatic gun

- Filter spray booth

- Washing machine with rinsing

- Immersion cleaning system

- Enclosed spray booth

- Washing machine with dryer

- Paint sprayer

- Degreasing washing machine

- Open spray booth

- Airless sprayer

- Part spray booth

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.