- Food industry

- Other Food Machinery

- Food crystallizer

- RONO Maschinenbau GmbH

Food crystallizer TYP PWU

Add to favorites

Compare this product

Characteristics

- Options

- for food

Description

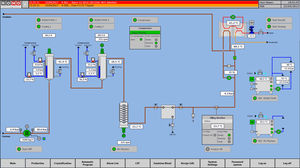

The pin worker unit is mainly used for intensive treatment of margarine and edible fat products, in order to achieve a proper crystallisation and right texture during the production process. Depending on product and desired consistency the pin worker unit can either be placed between the cooling steps or at the end of the cooling process.

The RONO pin worker unit is based on proven technique. Our further development enhanced the pin worker to meet best flexibility, highest standard of hygiene, very long life expectancy and easy maintenance in daily operation. The RONO pin worker unit offers highest flexibility to the production process and allows to work with a wide diversity of fat products. Adjustments to the level and intensity of treatment can be made by adjustment of the pin rotor speed.

Production capacity and volume of the pin worker unit offers a variable duration of kneading. Product crystallisation can be influenced by the choice of high or lower pressure production.

Types & Variations

Cylinder sizes

Ø 250 mm, 336 mm | Different lengths available

Volumes

The pin worker unit is available in various sizes and with different volumes: 25 ℓ, 50 ℓ, 100 ℓ, 120 ℓ und 180 ℓ

Modular Design

The pin worker unit can be build as stand-alone version or together with further pin worker units, mounted on a solid baseplate. Alternatively the PWU can be mounted on top of the RONOTHOR.

Working pressure range

Up to 120 bar

BENEFITS

Wide diversity of fat products

Highest flexibility to production process

Versatile adjustment possibilities

Hygienic design

Standard gearbox

Catalogs

No catalogs are available for this product.

See all of RONO Maschinenbau GmbH‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.