- Hydraulics - Pneumatics

- Pump

- Industrial vacuum unit

- RONO Maschinenbau GmbH

Industrial vacuum system RBS seriesautomatic

Add to favorites

Compare this product

Characteristics

- Applications

- industrial

- Other characteristics

- automatic

Description

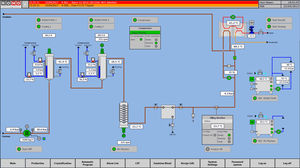

The RONO batch system is a highly flexible process system made for mixing, dispersing, homogenizing and emulsifying. It can be used for a wide range of food products and finds its main application especially in the production of mayonnaise, ketchup, sauces, dips and dressings.

The system can work under vacuum and it shows the innovative RONO technology particularly in the high efficiency of this batch system. This means that shortest production times can be achieved and 3–4 batches per hour can be easily realized even with large batch sizes, resulting in high capacities per hour. The RBS System can be designed with a multitude of variations and options to enable the food manufacturer to adapt his products to new market trends in order to meet the continuous changing of consumer requirements.

The modern PLC system is easy to operate and allows both automatic and recipe-controlled production as well as manual operation. The repetitive process parameters lead to very reliable productions with highest quality performance.

The innovative RBS system combines many years of experience in process engineering with the latest technology and best product know-how and guarantees maximum productivity, cost-efficiency and, above all, process safety.

Catalogs

No catalogs are available for this product.

See all of RONO Maschinenbau GmbH‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.