- Environment - Health - Safety

- Air Treatment and Noise Management

- High-performance fan

- Rosenberg Ventilatoren GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

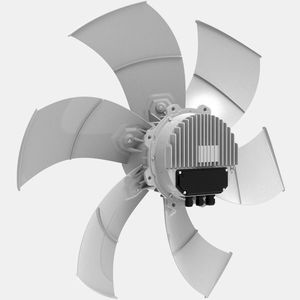

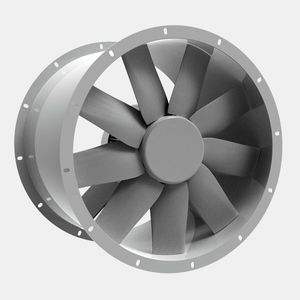

Wall-mounted fan ER/DRhigh-performanceaxialventilation

Add to favorites

Compare this product

Characteristics

- Type

- wall-mounted, high-performance

- Configuration

- axial

- Function

- ventilation

- Material

- galvanised steel, cast aluminum, plastic, steel

- Applications

- industrial

- Environmental characteristics

- long-life

- Other characteristics

- flange, compact

- Air flow

33,000 m³/h

(1,165,384.002 ft³/h)- Diameter

Min.: 200 mm

(7.874 in)Max.: 1,000 mm

(39.37 in)

Description

• asynchronous external rotor motor

• small depth

• universally usable in all installation positions

• speed is variable using auto transformers

Casing

The casings of the high-performance axial fans are manufactured from galvanised sheet steel and get an electrostatically applied powder plastic coating.

model EQ/DQ:

with square wall plate

model ER/DR:

pipe sleeve with double-sided standard flange for pipe installation

Impellers

The high-performance axial fans have aerodynamically shaped blades:

size from 200 to 300

made of painted and galvanised steel sheet

size from 315 to 630-6

made of plastic

size from 630-4 to 1000

made of die-cast aluminium

The impellers or blades are mounted directly on the rotor of the external rotor motors and are dynamically balanced on two levels with the rotor according to quality level G 2,5 / G 6,3 as per DIN ISO 21940-11.

Motors

size from 200 to 300

motor protection class IP44

size from 315 to 1000

motor protection class IP54

External rotor motors are used with moisture protection, with built-in ball bearings, and are designed with thermal overload protection. The drive by the external rotor motor provides a space-saving, compact and attractive design. The motor sits inside the impeller and is thus optimally cooled. For this reason, a 100% variable speed control can be guaranteed. Only well-dimensioned ball-bearings, fitted on both sides and with a long-life lubricant, are used. Both ball-bearing seats are ground to high precision in one work step to eliminate any vibration. External rotor motors are also characterised by an extremely low starting current.

Catalogs

World of fans

450 Pages

Fans with AC-drives

23 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.