- Environment - Health - Safety

- Air Treatment and Noise Management

- IP54 fan

- Rosenberg Ventilatoren GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

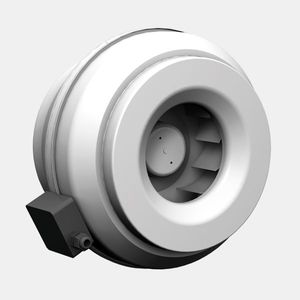

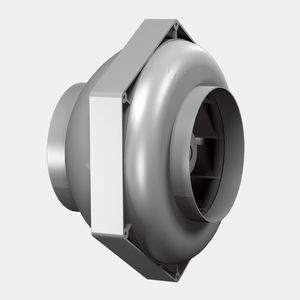

High-performance fan RIP54centrifugalventilation

Add to favorites

Compare this product

Characteristics

- Type

- high-performance, IP54

- Configuration

- centrifugal

- Function

- ventilation

- Material

- steel, aluminum, plastic

- Applications

- tube

- Other characteristics

- backward curved

- Air flow

2,500 m³/h

(88,286.667 ft³/h)- Diameter

Max.: 355 mm

(13.976 in)Min.: 100 mm

(3.937 in)

Description

• steel casing

• backward curved impellers

• can be used in all mounting positions

• speed is 100% infinitely variable using auto transformers or electronic control

Casing

The casings are made of galvanised sheet steel.

Impellers

Up to size 315L, backward curved high-performance impellers made of plastic are used, from size 355, backward curved, high-performance impellers made of aluminium are used. The impellers are mounted directly on the rotors of the external rotor motors and are dynamically balanced on two levels with the rotor according to quality level G 2,5 / G 6,3 as per DIN ISO 21940-11.

Size 100 - 250

backward curved high-performance impellers made of plastic

Size 250L - 315M

backward curved high-performance impellers made sheet steel

Size 355

backward curved high-performance impellers made of plastic

Electrical connection

The electrical connection is made through a terminal box mounted on the casing with protection class IP54.

Assembly

Rigid folded spiral-seam tubes (Spiro), flexible aluminium or plastic tubes with standardised diameter can be used. Rosenberg tube fans can be used in all mounting positions. When used over several floors of a building, the local fire safety regulations must be observed.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.