- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Mixer discharge unit HED-10for viscous productsbulkO-ring

Add to favorites

Compare this product

Characteristics

- Product applications

- for mixers, for viscous products, O-ring, bulk

Description

Any process is only as fast as its slowest operation. ROSS Discharge Systems used with change-can design mixers significantly improve production speed, efficiency, cleanliness and plant safety.

Benefits of Choosing a ROSS Discharge System

What does a ROSS Discharge System do?

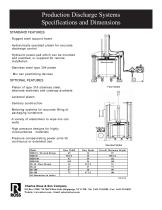

A Discharge System eliminates wasted hours of scraping heavy or sticky materials from a mix vessel. With push-button simplicity, the system can automatically discharge several hundred gallons of product in minutes — into bulk containers, filling or packaging equipment, or any downstream process. Yield from every batch is maximized because typically, only a thin layer of product remains on the vessel bottom.

How does a ROSS Discharge System work?

A Discharge System consists of a platen that is lowered hydraulically into a mix vessel. The platen is fitted with an O-ring which rides against the vessel wall. As the platen pushes down on the batch, sidewall surfaces are virtually wiped clean by the O-ring. Product is forced out through a valve on the side or center bottom of the vessel, or through the top of the platen. The platen may be jacketed to maintain batch temperature during discharge.

Semi-continuous Processing - Same-size vessels from multiple mixers can be rolled to a Discharge System for emptying, and then rolled away for cleaning as the next vessel is positioned underneath the platen. This flexibility can boost production on several process lines, all working with a single Discharge System. The discharge platen may be wrapped with a disposable plastic liner to keep it clean and always ready for the next vessel.

VIDEO

Catalogs

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.