- Metrology - Laboratory

- Inspection and Monitoring

- Automatic inspection system

- Rotary Precision Instruments UK

Automatic inspection system AccuScan XE200imeasurementgeometry

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Type

- measurement, geometry

Description

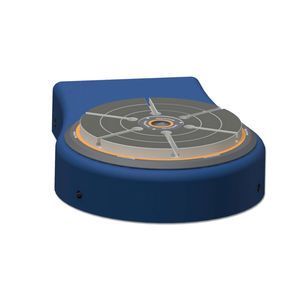

AccuScan XE200i

Fully understanding components geometry prior to assembly is critical when faced with the ever growing environmental pressures and increasing fuel prices. The significantly more reliable measurement data collected by iMAP enables rotor stacking software to accurately manipulate component parts, resulting in precisely aligned rotor assemblies. iMAP has been independently verified and proven to offer our customers significant operational improvements over their traditional measurement methods.

AccuScan’s capabilities deliver new levels of accuracy, flexibility and performance over a wide range of calibration and inspection applications.

IntelliProbe Corrects For Extreme Setup Errors

Software algorithms address profile distortion due to part misalignment, “intelligent probing” corrects for part off-centring errors of up to 2% of the part radius with negligible error.

Distribute Results Easily

Inspection Templates and Inspection Data Files are easily distributed via email for analysis using the free downloadable viewer or via PDF generated reports and CSV files.

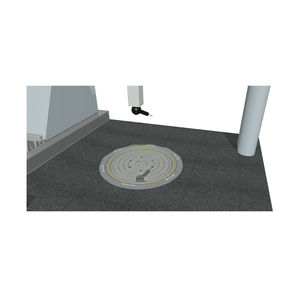

Reduces Inspection Time by up to 90%

AccuScan’s ability to measure 1,000 data points on 2 surfaces simultaneously per revolution will significantly reduce your process times compared with other available methods.

Unlimited Number of Surfaces

2 surfaces can be measured simultaneously with the total number of surfaces that can be measured unlimited.

Catalogs

No catalogs are available for this product.

See all of Rotary Precision Instruments UK‘s catalogsOther Rotary Precision Instruments UK products

PRODUCTS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.