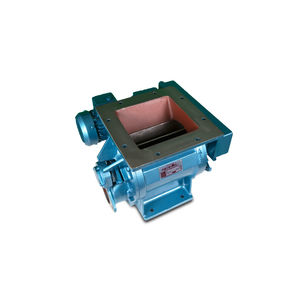

Dust collector rotary valve powderATEX

Add to favorites

Compare this product

Characteristics

- Applications

- powder, for dust collectors

- Other characteristics

- ATEX

Description

The prime function of a rotary valve is to regulate the flow from one chamber to another while maintaining a good airlock condition. The product is mainly in dry powder or granular form.

In the dust filtration field a good airlock is essential on cyclone and bag filter applications in order that the manufacturers quoted high dust collection efficiencies can be maintained. Airlocks are also important in the pneumatic conveying industry, where product is regulated into a pressure or vacuum conveying line while minimising air leakage.

With Rotolok there are no double standards, all our standard valves are precision machined for close tolerances and minimal eccentricities.

Pressure differentials to 20psi and temperatures to 400°C (752°F) are considered the norm and extreme pressures and temperatures can be accommodated with special designs. If your application requires such considerations contact the Rotolok Engineering team.

Rotolok Rotary Valves and Airlocks have ATEX Covered

Following successful completion of the rigorous testing process Rotolok can offer a complete range of Rotary Valves certified as suitable for use as an explosion barrier to a maximum of 10bar and for explosion isolation for St1 and St2 dusts.

The picture shows what 10 bar explosion pressure can do to 10mm thick carbon steel rotor vanes of inadequate design.

Due to careful design of the internal components the overall dimensions are very similar to our standard range of valves and we can offer a selection of optional features such as purged shaft seals, scalloped rotor pockets and staggered rotor pockets without the throughput being greatly reduced or the barrier efficiency being affected.

Catalogs

No catalogs are available for this product.

See all of ROTOLOK‘s catalogsRelated Searches

- Rotary valve

- Diverter valve

- Round-flange rotary valve

- Bulk material rotary valve

- Powder rotary valve

- Square-flange rotary valve

- ATEX rotary valve

- Pneumatic conveying diverter valve

- Powder diverter valve

- Grain rotary valve

- Gravity diverter valve

- Hygienic rotary valve

- Dust collector rotary valve

- Pellet rotary valve

- Grain diverter valve

- Gravity rotary valve

- Manual diverter valve

- Electrically-actuated rotary valve

- Pellet diverter valve

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.