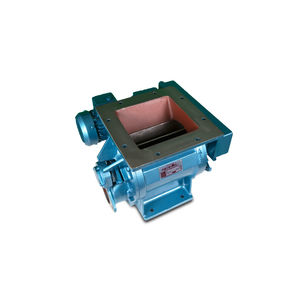

Powder rotary valve for grainfor dust collectorsround-flange

Add to favorites

Compare this product

Characteristics

- Applications

- powder, for grain, for dust collectors

- Type

- round-flange

- Other characteristics

- electrically-actuated

Description

The main feature of a Rotary Valve is to regulate the flow of material from one chamber to another while maintaining a good airlock condition. The material or product being handled is usually dry free flowing powder, dust or granules.

The granule type of product, especially if it is a plastic type, polythene or nylon etc., does not shear easily and consequently, without considerable care the standard drop-through type of valve leads to valve seizure and also considerable shock loadings.

To minimize these problems the Offset Rotary Valve ensures lower pocket fillage as its design means that the rotor is still being filled in the upward cycle with the pellets falling away at the shear point. Similarly, the pelican beak distributes the product across the full width of the rotor.

Catalogs

No catalogs are available for this product.

See all of ROTOLOK‘s catalogsRelated Searches

- Rotary valve

- Diverter valve

- Round-flange rotary valve

- Bulk material rotary valve

- Powder rotary valve

- Square-flange rotary valve

- ATEX rotary valve

- Pneumatic conveying diverter valve

- Powder diverter valve

- Grain rotary valve

- Gravity diverter valve

- Hygienic rotary valve

- Dust collector rotary valve

- Pellet rotary valve

- Grain diverter valve

- Gravity rotary valve

- Manual diverter valve

- Electrically-actuated rotary valve

- Pellet diverter valve

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.