Biological sewage treatment plant ITSEIFA seriesactivated sludge

Add to favorites

Compare this product

Characteristics

- Options

- biological, activated sludge

Description

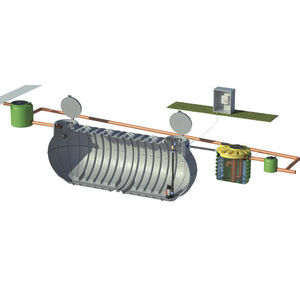

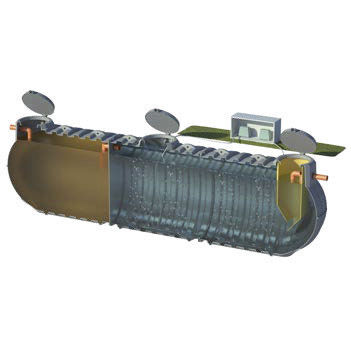

ONE-PIECE TREATMENT PLANTS

ACTIVATED SLUDGE PLANTS

1.SLUDGE SEDIMENTATION AND DIGESTION SECTION: stilling area in which the solid part of the effluent sédiments and accumulâtes on the bottom; a bacterial flora develops there and transforms the putrescible material in the sludge into inert sludge. carbon dioxide and water.

2.OXYGENATION SECTION: area in which forced air is blown in to move and oxygenate the effluent. Aérobic bacteria develop in this environment, oxidising the residual organic component and the nitrogen.

3.FINAL SEDIMENTATION SECTION: stilling area in which any residual sludge decants and is gravity fed once again to the oxidation area.

4.DIFFUSER PLATES in microbored rubber for even distribution of the air within the oxygénation section.

5.BLOWERS-COMPRESSORS with side channel to push the air toward the oxygénation section diffuser plates.

SPECIFICATIONS

TECHNICAL CHARACTERISTICS: Treatment of domestic raw sewage by primary sédimentation and anaérobie sludge digestion treatment in a septic tank and subséquent secondary activated sludge aérobic digestion treatment. The Rototec one-piece treatment plant is sized for average domestic discharge: a spécifie discharge flow rate of 200 l/PE x day and a pro capita organic pollution load of 60gBOD/PE x day; it is important that grease and foam be separated upstream of the activated sludge tank, as these might hâve a négative effect on the treatment performance, which in normal operating conditions reaches up to 90% (percentage removal of the organic load as BODs). The treated effluent complies with the émission limits in table 3 of Leg. Decree 152/20 06 for discharge to a surface watercourse.

Catalogs

No catalogs are available for this product.

See all of ROTOTEC SPA‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.