- Products

- Catalogs

- News & Trends

- Exhibitions

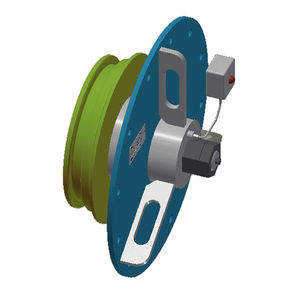

Monobloc wheel bearingflangedgrooved

Add to favorites

Compare this product

Characteristics

- Type

- monobloc

- Applications

- bearing

- Other characteristics

- flanged, grooved

Description

Due to the toothed drive, no weight preload is required for deflection. In the reversing wheel for System 65, the chain is deflected in a relaxed state. This results in reduced chain crawler tractive force. Less surface pressure in chain links leads to reduced wear.

The thrust ring of the reversing wheel for System 65 is made of GS material or has a welded structure; the hub cross is made of GG material or has a welded structure. The hub is drilled and grooved for perfect fit. Flanged wheel diameter with tread diameter up to 1010 = tread diameter + approx. 400 m; with tread diameter from 111 0 mm = tread diameter + approx. 500 mm.

Application areas of reversing wheels for System 65

• Bucket elevator System 65

• Heavy operating conditions

Advantages of reversing wheel for system 65

• The bearing ring and the hub plate are stable welded constructions

• Weight-loaded initial tensioning is not required at the deflection due to the interlocked drive. The chain is redirected into uncompressed condition: reduction in wear

Catalogs

No catalogs are available for this product.

See all of RUD‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.