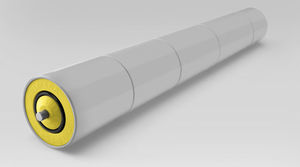

Chain drive conveyor roller 138 seriesPVCsteel

Add to favorites

Compare this product

Characteristics

- Drive mechanism

- chain drive

- Material

- PVC, steel

- Diameter

Min.: 40 mm

(2 in)Max.: 63 mm

(2 in)

Description

These rollers have the same construction characteristics of the driven series 135 except for the sprocket as they transmit the motion to the tube by friction, through the assembled sleeve element at the tube end. The pinions are interchangeable and easily replaced by Polyamide pinions of 135 series, therefore modifying working conveyors without problems. The two series together allow different combinations with maximum flexibility and system modularity. The friction rollers of 138 series guarantee a good units handling even in case of dampness or lubricants. They are supplied in sendzimir zinc-plated steel tube (Z exec.) except for 138/Q4-S4 types, or in special shock resistant quiet PVC (V exec): on request also in AISI 304 stainless steel. Pinions are either in Polyamide or steel for transmission with:

simple tangential chain, P1C version

chain loops, P2C version

Rollers with Polyamide pinions are suited for light and medium loads; the PVC tube version or AISI 304 stainless steel has the ideal application in corrosive, food and wet environments and is especially noiseless. As the steel pinions have a greater heat discharging capacity, they are used for medium heavy loads at maximum speed, or for long stop times. The peripheral speed may reach 0.5 m/s but in case of long accumulation times it is better not to exceed 0.3 m/s. Application temperatures range from –5° C to +40° C. For the transmission calculation and for the accumulation pressure please refer to chapter Application indications and design criteria.

Catalogs

Related Searches

- Rail conveyor

- Transport conveyor

- Belt conveyor

- Horizontal conveyor

- Conveyor roller

- Unloading conveyor

- Curved rail conveyor

- Metal conveyor roller

- Vertical conveyor

- Slip-on conveyor roller

- Steel conveyor roller

- Stainless steel conveyor roller

- Plastic conveyor roller

- Motorized roller

- Tubular conveyor

- PVC-coated conveyor roller

- Conveyor motorized roller

- Heavy load conveyor roller

- Driven conveyor roller

- Chain drive conveyor roller

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.