Slip-on conveyor roller steelfor heavy loadslow-noise level

Add to favorites

Compare this product

Characteristics

- Drive mechanism

- slip-on

- Material

- steel

- Other characteristics

- for heavy loads, low-noise level

- Diameter

Max.: 219 mm

(9 in)Min.: 108 mm

(4 in)

Description

RULMECA carried out an extensive testing campaign, both in the in-house laboratory and in real application on the field and is now proud to present a new solution for low noise rollers.

RULMECA takes very seriously the issues related to roller noise with:

- The best equipment available;

- A specific Test room designed and prepared to meet the highest standards;

- Strong partnerships with engineering companies with specific experience in noise issues;

FEATURES AND BENEFITS:

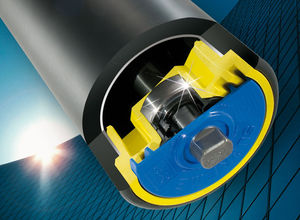

• The RULMECA low noise roller has been specially machined to achieve very precise values of TIR and MIS. This allows high running smoothness and a reduction of noise emissions up to 12 dB (A) Lwa, compared to standard rolls.

• The high reductions in vibrations are also achieved by an accurate dynamic balancing procedure of class G12 according to DIN1940.

• With additional internal damping elements and the above actions, a whole noise reduction of 14 dB (A) Lwa is achievable. (registered design BRD 202010007189.5)

• These HIGH QUALITY RULMECA ROLLERS are recommended in high speed conveying applications where very low noise levels are required.

• Additional possibilities are:

- Use of RULMECA ‘TOP’ or ‘SUPREME’ rollers for special applications, (see separate flyer)

- Decoupling from conveyor steel structure with special damping solutions

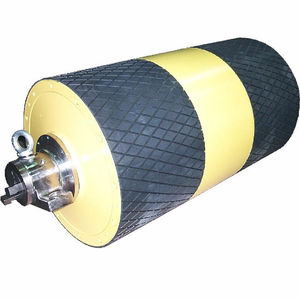

- Special roller coatings (HDPE/LDPE/PU/Rubber)

- Special connecting elements, etc.

We have the knowledge and the best options to find the right solution for your material handling applications.

Catalogs

No catalogs are available for this product.

See all of Rulli Rulmeca‘s catalogsRelated Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Conveyor roller

- Discharge conveyor

- Curved rail conveyor

- Metal conveyor roller

- Vertical rail conveyor

- Slip-on conveyor roller

- Steel conveyor roller

- Stainless steel conveyor roller

- Plastic conveyor roller

- Motorized roller

- Tubular conveyor

- PVC-coated conveyor roller

- Conveyor motorized roller

- Heavy load conveyor roller

- Driven conveyor roller

- Chain drive conveyor roller

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.