- Packing - Handling - Logistics

- Conveying

- Belt conveyor

- Rulli Rulmeca

Belt conveyor horizontalcurvedvertical

Add to favorites

Compare this product

Characteristics

- Technology

- belt

- Form

- horizontal, curved, vertical, tubular

- Function

- transport, unloading

Description

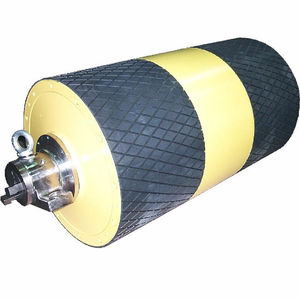

The pipe conveyor is a system conceived to solve many of the problems existing with conventional conveyor systems. At the loading point of the material, the Pipe Conveyor is open as a conventional belt conveyor, then it closes up into a pipe shape containing the conveyed material and returns to open at the discharge point. As the material is wrapped around by the belt, there is no spillage or training problems and this keeps pollution under control. Pipe conveyors are available in horizontal curves as well as vertical curves.

What do Rulmeca supply within Pipe Conveyors?

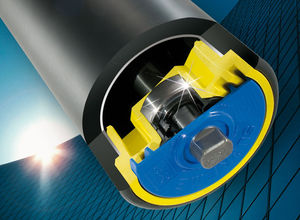

Rulmeca produces the rollers and roller supporting brackets for every diameter of Pipe, with its own moulds for standard dimensions and execution, and under customer drawings for non standard executions.

Rulmeca's long term experience in these products grants technical support to the pipe conveyor designers and engineering companies in the roller and bracket selection.

Thanks to the product research and development in previous years, Rulmeca can propose a new advantageous execution of roller disposal onto the frame and a new locking system to the brackets – an alternative to the standard riveted plate locking system.

Catalogs

No catalogs are available for this product.

See all of Rulli Rulmeca‘s catalogsRelated Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Conveyor roller

- Discharge conveyor

- Curved rail conveyor

- Metal conveyor roller

- Vertical rail conveyor

- Slip-on conveyor roller

- Steel conveyor roller

- Stainless steel conveyor roller

- Plastic conveyor roller

- Motorized roller

- Tubular conveyor

- PVC-coated conveyor roller

- Conveyor motorized roller

- Heavy load conveyor roller

- Driven conveyor roller

- Chain drive conveyor roller

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.