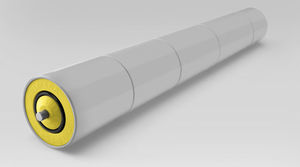

Conveyor roller RDR BL3

Add to favorites

Compare this product

Description

LOW, MEDIUM OR HIGH SPEEDS WHICH ARE EITHER SET OR VARIED BY THE CLIENT

CONSTANT HIGH TORQUE THROUGHOUT THE SPEED RANGE

FREQUENT STOP/START CYCLES

OPTIMISED WORKING CONSUMPTION

LOW LEVELS OF SYSTEM NOISE

SAFETY FOR LINE OPERATORS

Its excellent value for money makes the RDR BL3 Drive Roller the ideal choice for satisfying even the most demanding of clients.

Rulmeca Drive Rollers (RDR) are designed to play a key role in industrial applications in which roller transportation is an important part of the production process.

According to the characteristics of the items to be conveyed, the overall configuration of the system and environmental conditions, it is possible to configure the Drive Roller in complete safety and with the utmost efficiency.

As well as being classified as an electrically-safe system as it is powered by 24V DC, the Drive Roller is an extremely silent, compact, efficient and long-lasting solution which does not require maintenance of its functional parts.

The motor unit, the technological heart of the Drive Roller, is - in the standard set-up proposed - fitted inside a 50 mm Ø tube with the finish agreed with the client.

In order to select the right gear reduction ratio, thus defining the rotation speed and the available torque, it is necessary to take into consideration the weight, size, material and base profile of the items to be conveyed, as well as the desired transportation speed and the working dynamics of the conveyor.

Please contact Rulli Rulmeca S.p.A. for any further information regarding the correct configuration of the Drive Roller and of all the relative components.

Catalogs

DriveRoller

48 Pages

RDR_BL3_Catalogue

52 Pages

Related Searches

- Rail conveyor

- Transport conveyor

- Belt conveyor

- Horizontal conveyor

- Conveyor roller

- Unloading conveyor

- Curved rail conveyor

- Metal conveyor roller

- Vertical conveyor

- Slip-on conveyor roller

- Steel conveyor roller

- Stainless steel conveyor roller

- Plastic conveyor roller

- Motorized roller

- Tubular conveyor

- PVC-coated conveyor roller

- Conveyor motorized roller

- Heavy load conveyor roller

- Driven conveyor roller

- Chain drive conveyor roller

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.