- Packing - Handling - Logistics

- Conveying

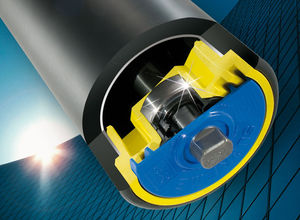

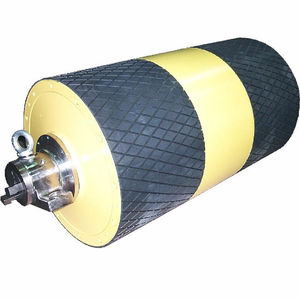

- Belt cleaner

- Rulli Rulmeca

Belt cleaner

Add to favorites

Compare this product

Description

The problem of conveyed material adhering to the conveyor belt, occurs frequently with wet or sticky material, resulting in frequent downtime for maintenance, and clean up, with consequent loss of production.

The problems of belt cleaning have increased in parallel with the development of conveyors of ever increasing lengths, speed and belts widths, necessary to satisfy the need to maximise load capacities.

Therefore, the use of cleaning equipment has become an indispensable requirement to assure general plant efficiency and to reduce the periods of service needed for maintenance.

There has been a notable development of this equipment in recent time for differing reasons: prolonging the life of the conveyor limiting the deterioration of the belt, improving the energy efficiency of the installation,

reducing loss of material thereby increasing the load capacity, eliminating a major cause of wear on the return rollers.

Belt cleaners series P for uni-directional belts

Belt cleaners series R for reversible belts

Belt cleaners series H for reversible and uni-directional belts for tangential applications

Belt cleaners series D patented for single directional belts

Simple plough cleaners

Catalogs

No catalogs are available for this product.

See all of Rulli Rulmeca‘s catalogsRelated Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Conveyor roller

- Discharge conveyor

- Curved rail conveyor

- Metal conveyor roller

- Vertical rail conveyor

- Slip-on conveyor roller

- Steel conveyor roller

- Stainless steel conveyor roller

- Plastic conveyor roller

- Motorized roller

- Tubular conveyor

- PVC-coated conveyor roller

- Conveyor motorized roller

- Heavy load conveyor roller

- Driven conveyor roller

- Chain drive conveyor roller

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.