Slip-on conveyor roller PL, PLF seriesplastic

Add to favorites

Compare this product

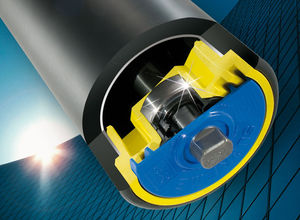

Characteristics

- Drive mechanism

- slip-on

- Material

- plastic

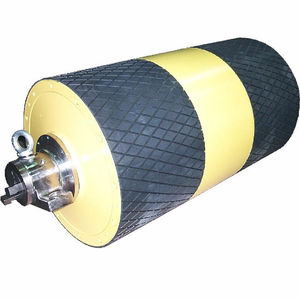

- Diameter

Min.: 89 mm

(4 in)Max.: 140 mm

(6 in)

Description

In conveyors used to transport very corrosive materials and where difficult working conditions prevail: the extraction industries and in the mining of salt, chemical industries, fertiliser manufacture and in marine environments which require corrosion resistant rollers.

These rollers demonstrate particular resistance to the presence of high humidity and water, and also to corrosive elements present in the environment or in the conveyed material itself.

The design of the rollers utilises plastic materials for the most critical parts, which, excellently and economically, substitute for traditional materials such as stainless steel, bronze and aluminium.

Testing and actual plant trials have well demonstrated the efficiency and versatility of these rollers. The characteristics designed into them provide a long working life even in the most severe environment, and

when one considers their low purchasing and maintenance cost, PL/PLF rollers provide the ideal solution for severe applications.

The functioning temperatures recommended are:

10° to +50°C for PL rollers

10° to + 70° for PLF rollers

Catalogs

BULK Handling rollers

318 Pages

Unit Handling Drum Motors

116 Pages

Related Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Conveyor roller

- Discharge conveyor

- Curved rail conveyor

- Metal conveyor roller

- Vertical rail conveyor

- Slip-on conveyor roller

- Steel conveyor roller

- Stainless steel conveyor roller

- Plastic conveyor roller

- Motorized roller

- Tubular conveyor

- PVC-coated conveyor roller

- Conveyor motorized roller

- Heavy load conveyor roller

- Driven conveyor roller

- Chain drive conveyor roller

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.