Slip-on conveyor roller TOPthermoplasticabrasion-resistant

Add to favorites

Compare this product

Characteristics

- Drive mechanism

- slip-on

- Material

- thermoplastic

- Other characteristics

- abrasion-resistant

- Diameter

Min.: 89 mm

(4 in)Max.: 133 mm

(5 in)

Description

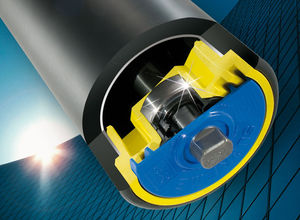

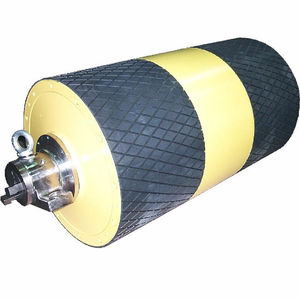

Rulmeca is proud to introduce the new TOP roller, a totally thermoplastic roller with the exception of the steel in the ball bearing and the shaft.

The new TOP roller has a lower weight with respect to a steel roller (about 50%), which means a lower power consumption during start/stop operation of the belt conveyor and therefore reduction of power requirements on the plant, easier mounting/maintenance operations, preventing back injuries of the operator and guaranteeing a safer intervention, especially in application where roller mounting or replacement might be critical (suspended belt conveyor, difficult access, long conveyors…), easier/cheaper transportation

Furthermore the low level of abrasion and corrosion of this roller (wear resistant) guarantees a longer life of the roller and a lower maintenance of the whole plant.

The TOP is belt friendly, since HDPE tube will not wear the belt high resistance to chemical agents. It doesn’t rust, it is suitable for a wide variety of applications and it has a low noise emission (due to thermoplastic noise absorption).

Thanks to the self-cleaning roller surface, there is a prevention of build up of material, main cause of belt mis-tracking and less spillage from the belt.

The roller low running resistance sealing system means a lower motor torque need in conveyor starts, a lower motor power size, a reduction of energy consumption of the belt conveyor (added effect to that of the lower weight) and a lower belt consumption.

Catalogs

BULK Handling rollers

318 Pages

Bulk Handling Motorized Pulleys

104 Pages

Related Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Conveyor roller

- Discharge conveyor

- Curved rail conveyor

- Metal conveyor roller

- Vertical rail conveyor

- Slip-on conveyor roller

- Steel conveyor roller

- Stainless steel conveyor roller

- Plastic conveyor roller

- Motorized roller

- Tubular conveyor

- PVC-coated conveyor roller

- Conveyor motorized roller

- Heavy load conveyor roller

- Driven conveyor roller

- Chain drive conveyor roller

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.