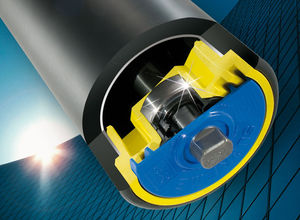

Slip-on conveyor roller PSV, RTL, MPSsteellower

Add to favorites

Compare this product

Characteristics

- Drive mechanism

- slip-on

- Material

- steel

- Other characteristics

- lower

- Diameter

Min.: 60 mm

(2 in)Max.: 180 mm

(7 in)

Description

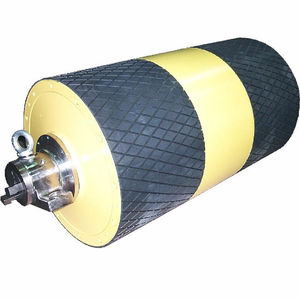

The straight tracking of the belt may be compromised by the type of conveyed material, specially when this material is sticky and thereby adheres easily to the belt surface.

In this case, material is also deposited on the return rollers that support the belt, adding an irregular addition of scale to the roller itself.

As a consequence, not only wear and tear of the belt occurs, but forces are brought into play to move the belt away from its correct track.

Return rollers with spaced rubber rings contribute largely to eliminating the build up of scale that forms in certain conditions on the belt surface.

The rings are pointed, assembled at intervals, in the central part of the roller, where they have the scope to break up the scale which normally is present at the belt centre; meanwhile flat rings mounted in groups at the extremities of the belt, support and protect the belt edges, also in cases of limited belt wandering.

Return rollers with rings should not be used as belt tensioning devices.

The rubber rings may function in the temperature range between – 20°C + 80 °C.

Catalogs

Related Searches

- Rail conveyor

- Belt conveyor

- Conveyor roller

- Discharge conveyor

- Curved rail conveyor

- Metal conveyor roller

- Vertical conveyor

- Slip-on conveyor roller

- Steel conveyor roller

- Stainless steel conveyor roller

- Plastic conveyor roller

- Motorized roller

- Tubular conveyor

- PVC-coated conveyor roller

- Conveyor motorized roller

- Heavy load conveyor roller

- Driven conveyor roller

- Chain drive conveyor roller

- Galvanised steel conveyor roller

- Single-phase/three-phase drum motor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.