Lateral guide for conveyor S, F, R series

Add to favorites

Compare this product

Description

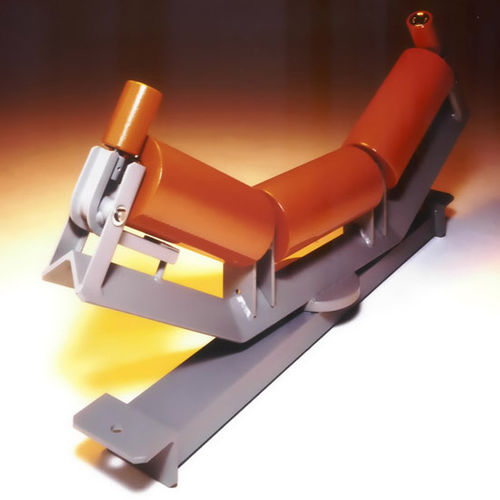

Sometimes the difficult working conditions of the plant results in a lateral movement of the belt. In this case a self-centralising troughing set is used which acts in a way that corrects the belt tracking and maintains it constantly in the central position.

The self-centralising troughing set is designed as a series of rollers arranged in a trough positioned onto the supporting transom which itself is fixed to a slewing ring which permits rotation.

The slewing ring (a large ball bearing) permits a rotation limited to 5-8 degrees and is sized in proportion to the vertical loading; a tapered roller bearing assembled to the shaft of the slewing ring, absorbs any side forces or overturning pressures.

The installation of the self-centralising troughing sets is advised to be positioned on the upper strand rather than the return section, and used only when the working conditions require.

Catalogs

Related Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Conveyor roller

- Discharge conveyor

- Curved rail conveyor

- Metal conveyor roller

- Vertical rail conveyor

- Slip-on conveyor roller

- Steel conveyor roller

- Stainless steel conveyor roller

- Plastic conveyor roller

- Motorized roller

- Tubular conveyor

- PVC-coated conveyor roller

- Conveyor motorized roller

- Heavy load conveyor roller

- Driven conveyor roller

- Chain drive conveyor roller

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.