- Industrial machines and equipment

- Surface Treatment Equipment

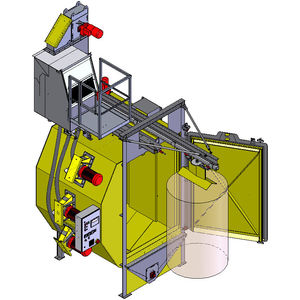

- Belt shot blasting machine

- RUMP STRAHLANLAGEN GmbH & Co. KG

Belt shot blasting machine CUBESTA®for metalautomatic

Add to favorites

Compare this product

Characteristics

- Type

- belt

- Applications

- for metal

- Other characteristics

- automatic

Description

Rubber belt tumble machines

These machines are suitable for the automatic shotblasting of tumble-proof casted, forged, stamped and flame-cut parts in batch operation as well as for the surface hardening of springs.

The tumble belt is made of perforated rubber with supporting tissue. Depending on the model, it is suitable for load weights up to 20 or 30 kg.

The parts are either loaded manually or with a hydraulic tilting device out of a transport container onto the belt and are continuously circulated during the blasting process. After the blasting, the discharge of the workpieces takes place by a changeover of the conveying direction of the tumble belt. In that case, the workpieces are dropped onto an additional discharge belt, a vibrating conveyor channel or also directly into an underneath transport container.

Steel belt tumble machines

These machines are suitable for the automatic shotblasting of tumble-proof casted, forged, stamped and flame-ut parts in batch operation.

The tumble belt consists of high wear resistant manganese hard steel plates and cast chain links. Depending on the model, it is suitable for load weights up to 125 or 200 kg.

The parts are loaded from a transport container onto the belt by means of a hydraulic tilting device and are continuously circulated during the blasting process. After the blasting, the discharge of the workpieces takes place by a changeover of the conveying direction of the tumble belt. In that case, the workpieces are dropped onto an additional discharge belt, a vibrating conveyor channel or also directly into an underneath transport container.

Other RUMP STRAHLANLAGEN GmbH & Co. KG products

Shot blasting machines

Related Searches

- Blast machine

- Metal shot blasting machine

- Automatic blast machine

- Continuous shot blasting machine

- Belt blast machine

- Hook shot blasting machine

- Roller conveyor blast machine

- Rotating table shot blasting machine

- Profile shot blasting machine

- Tube shot blasting machine

- Wheel rim shot blasting machine

- Pipe shot blasting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.