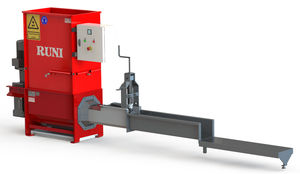

Waste recycling waste compactor SK240stationaryscrewtop-loading

Add to favorites

Compare this product

Characteristics

- Type of waste

- waste recycling

- Mobility

- stationary

- Type

- screw

- Loading

- top-loading

Description

RUNI SK240 screw compactors are the second largest machines for compacting EPS and are recommended for an annual volume of 30-50 tonnes. The screw compactor can compact the EPS (also known as airpop) at a ratio of up to 50:1. . The density of the blocks is approx. 350 kg/m³, and the compacted blocks can be stacked on a pallet and sold for recycling. 20 tonnes can be loaded on a truck or in a container

TURN WASTE TO VALUE!

Which Machine to Choose?

The material can be fed manually into a 45° hopper or a conveyor belt into a vertical hopper. The pre-crusher placed inside the hopper will cut the EPS into smaller pieces, which fall into the screw. The screw and the automatic hydraulic jaws compress the EPS into the solid and uniform blocks.

The density and size of the EPS are crucial for the choice of pre-crusher. The incorporated sensors ensure easy operation with an automatic start and stop function and adjustable speed. It is also possible to place the compactor below a silo if you are handling large quantities. The optional automatic block divider and crane ease the handling of the blocks after compaction. The block divider cuts the blocks in predetermined lengths for easy stacking on a pallet.

Benefits of the SK240:

Save space and handling costs through rapid, efficient waste management.

Save energy – no heat required in the process. The friction of the screw and the material generates enough heat to make the blocks cohesive.

Profit from selling compacted EPS for recycling into new PS-pellets.

VIDEO

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.