- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

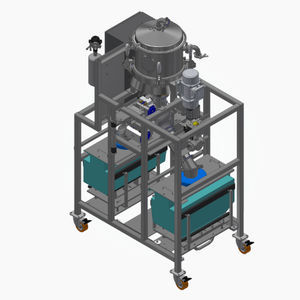

Powder recovery system AMPro®Labfor 3D printing

Add to favorites

Compare this product

Characteristics

- Type

- powder

- Applications

- for 3D printing

Description

Optimize your AM powder recovery process

The Russell AMPro®Lab Sieve Station is a highly flexible system, best suited for reclaiming small-batches of additive manufacturing (AM) powders.

Compatible with a wide range of bottle sizes, the system can be integrated into a bottle-to-bottle transfer process, easily connecting to 3D printers. It can be further customized to include inert gas purging, feed assist technology and pneumatic conveying.

Enhanced efficiency for small-scale powder handling

The units compact and efficient design offers the perfect solution for small scale printers handling small quantities of powder. And with easy to disassemble contact parts, the AMPro®Lab Sieve Station can increase productivity by reducing downtime spent cleaning between batches.

It ensures optimum sieving through three distinct adjustment modes: controlled feeding, sieve inclination, and variable vibrasonic controls. Utilizing the Russell Vibrasonic® Deblinding System, the unit applies high-frequency vibrations to the mesh, eliminating contaminants and product oversize.

Catalogs

No catalogs are available for this product.

See all of Russell Finex‘s catalogsRelated Searches

- Russell Finex screener

- Russell Finex bulk material screener

- Russell Finex vibrating screener

- Mobile screening unit

- Recovery unit

- Russell Finex recycling screener

- Russell Finex food industry sieve

- Russell Finex compact screener

- Russell Finex dry screening screener

- Russell Finex powder screener

- Stainless steel sieving machine

- Process screening machine

- Circular vibrating sieving machine

- Solid/liquid sieving machine

- Heavy-duty screening unit

- Particle screening machine

- Liquid sieving machine

- Rotary screening machine

- Wet screening sieving machine

- Russell Finex screener for pharmaceutical applications

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.