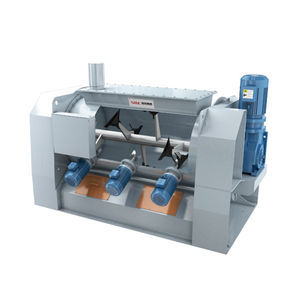

Plough mixer LDH Seriesfluidized bedbatchsolid/liquid

Add to favorites

Compare this product

Characteristics

- Technology

- plough, fluidized bed

- Batch/continuous

- batch

- Product type

- solid/liquid, powder, granules

- Configuration

- horizontal

- Other characteristics

- automatic, stainless steel, high-speed, variable-speed, single-shaft, low-pressure, high-performance, explosion-proof, double, with cooler, clean-in-place (CIP), high-pressure, energy-efficient, combined heating/cooling, proportional, 3-shaft, high precision, hygienic, high-capacity

- Applications

- for the food industry, for the chemical industry, for the cosmetics industry, construction, for bulk materials, for the paper industry, for pasty products, high-temperature

- Engine power

Max.: 5.5 kW

(7.48 hp)Min.: 1.5 kW

(2.04 hp)- Capacity

Max.: 20 m³

(706.29 ft³)Min.: 0.1 m³

(3.53 ft³)- Empty weight

Max.: 18,900 kg

(41,667.4 lb)Min.: 385 kg

(848.8 lb)

Description

Ploughshare Mixer

Plough Mixer consists of horizontal & cylindrical drum vessel, plough shaped shovel agitator, drive unit and chopper. The mixing elements create a mechanical fluidized bed mixing actions to hurl materials away from the wall of vessel into free space in crisscross direction and inversely back again. A fluid bed generated mechanically in this way, whereby the raw material is constantly involved in the mixing process, ensures maximum mixing intensity at even the highest feed rates and shortest residence times and allows addition of liquids. The Ploughshare Mixer guarantees extremely high performance and fully optimized processes to adapt specific mix. Plow Mixer has very fast mixing speed to get ideal mixing homogeneity in very short time and can also be used to solve multiple applications including mixing, drying, coating, reacting in one single machine. In order to meet big capacity requirement, we can also design batch and continuous mixing process for client.

Features:

● Perfect mixing result within short mixing time

● High speed chopper for de-agglomeration

● Multiple mixing elements design

● High Shearing Mixing in Movement Zone

● Heating/cooling jacket and vacuum design is optional

● Heavy duty work for complex materials

● Flexible Design for different applications and industries

● Batch or continuous process

● Center or Big bomb-bay discharge valve is optional

Applications:

● Dry Powder

● Dry Powder with liquid additives

● Slurry

● Paste and Wet

VIDEO

Catalogs

No catalogs are available for this product.

See all of S&L Mixer Ltd.,Co‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Homogenizer for the food industry

- Solid blender

- Vertical agitator

- Agitator for the chemical industry

- Stainless steel agitator

- In-line mixer

- Powder blender

- Solid/liquid homogenizer

- Horizontal blender

- Agitator for the pharmaceutical industry

- Paddle blender

- Construction agitator

- Homogenizer for the cosmetics industry

- Compact agitator

- Vacuum homogenizer

- High-speed homogenizer

- Automatic homogenizer

- Laboratory homogenizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.