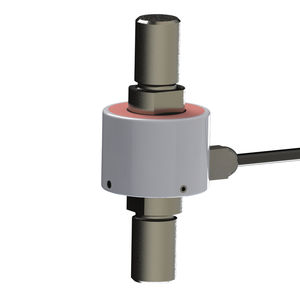

Tension/compression load cell MD5005Sbeam typestrain gaugedigital

Add to favorites

Compare this product

Characteristics

- Type

- tension/compression

- Form

- beam type

- Technology

- strain gauge

- Output signal

- analog, digital

- Other characteristics

- steel, IP65

- Rated load

1 t, 3 t, 5 t

(1.1 us ton, 3.31 us ton, 5.51 us ton)

Description

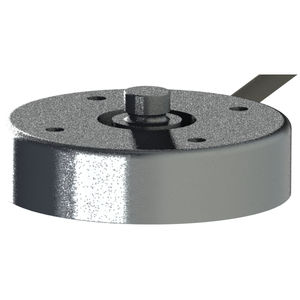

Pin load cells are used to measure applied weight in the central part of the transducer (G area) in comparison to the two extremities of the load cells (E area).

The body of the load cell is realized with rectified cylindrical surface to allow the installation of the running gear in the central part. It guarantees that the transducers are bound to the two extremities, maintaining measuring axis correctly oriented on the axis of the force that should be measured.

These load cells are designed for difficult industrial use and environments, where safety is fundamental. The safe factor changes according to the model and can reach 200% against mechanical overloads, for static or almost static loads.

The transducers are designed thanks to FEA analysis, in order to have the best working geometry. The body of the load cell can be realized in high resistance steel or 17-4 PH stainless steel, according to the need of the customer and of the application.

There are different versions of the transducers:

S (standard) version: standard production

L (long) version: realized according customers’ requests

MD transducers have a typical sensitivity of 1 mV/V and they are available with built-in electronics, with analog or digital output.

Catalogs

No catalogs are available for this product.

See all of S2Tech srl‘s catalogsRelated Searches

- Force sensor

- Tension/compression force sensor

- Steel force transducer

- Strain gauge force transducer

- Stainless steel force sensor

- Weighing force sensor

- Beam type force transducer

- Compression force sensor

- Weighing terminal

- Digital weighing terminal

- Aluminum force sensor

- IP65 force sensor

- Analog force sensor

- High-precision force sensor

- Compact force sensor

- Precision force sensor

- Button type force sensor

- Panel-mount weighing terminal

- S-beam force sensor

- Miniature force transducer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.