- Packing - Handling - Logistics

- Packing and Packaging

- Horizontal bagging machine

- SAGBIL PACKAGING MACHINES

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

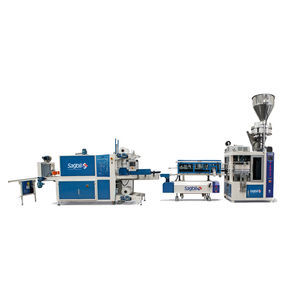

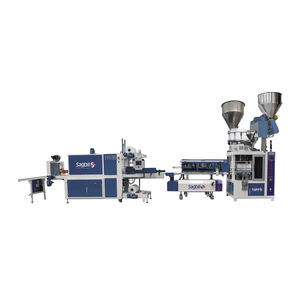

Horizontal bagging machine SAM FPM-125HFFSPLC-controlledfor the food industry

Add to favorites

Compare this product

Characteristics

- Type

- horizontal

- Technology

- HFFS

- Operational mode

- PLC-controlled

- Application domain

- for the food industry

- Product applications

- for granulates

- Other characteristics

- with multi-head weigher, with servo-motor, continuous-motion

- Throughput

Min.: 12 p/min

Max.: 26 p/min

Description

SAM FPM 125 Fully Automatic Tea Filling and Packing Line automatically takes and fills flat-bottomed ready-made paper packages. The filled packages move towards the bag closing machine on the band. In the bag closing machine, the excess paper is cut, the first fold is made, the last fold is made with hot glue and it comes out of the machine with the mouth closed. The dates of the packages coming out of the bag closing machine are automatically discarded and the packages are labeled by moving towards the labeling machine. Finally, the labeled packages move towards the automation shrink machine. In the shrink machine, the packages are grouped and shrinked.

TECHNICIAL SPECIFICATIONS:

* Multihead scale filling system is used for tea filling.

* All control is done from touch PLC screen.

* There is automatic lubrication in the whole system.

* There is a dust suction system on the filling system.

* There is a speed-adjustable vibration system.

PRODUCTS SUITABLE FOR PACKAGING:

Tea

CAPACITY:

-For 250 gr: max 26 bags/minute

-For 500 gr: max 22 bags/minute

-For 1000 gr: max 12 bags/minute

VIDEO

Catalogs

Other SAGBIL PACKAGING MACHINES products

FULL AUTOMATIC FILLING AND PACKAGING MACHINES

Related Searches

- Bagging machine

- Automatic bagging machine

- FFS bagging machine

- Vertical bagging machine

- Bulk material bagging machine

- Bagging machine for the food industry

- Horizontal bagging machine

- VFFS bagging machine

- Granulate bagging machine

- Powder bagging machine

- High-speed bagging machine

- HFFS bagging machine

- PLC-controlled bagging machine

- Semi-automatic bagging machine

- Bagging machine with servo-motor

- Multipack bagging machine

- Bagging machine with multi-head weigher

- Salt bagging machine

- Continuous-motion bagging machine

- High-speed bagging machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.