Fiberglass sheet pile

Add to favorites

Compare this product

Characteristics

- Material

- fiberglass

Description

Sheet piles are important elements of a building. They are narrow and long beams that are sunken into the ground and function as a supporting wall, water containment or for unstable soil. Their use is widespread and, in recent years, composite material sheet piles are replacing those made of steel.

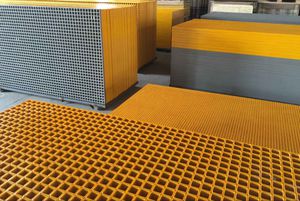

Description and characteristics of resin glass sheet piles

Resin glass sheet piles thanks to their structural features, lightness, load capacity and water resistance are considered a natural evolution of traditional steel sheet piles. The success of the sheet piles made through the pultrusion of composite materials is almost universal and can be considered a new standard in building or other projects.

Saimex s.r.l. is aware of all the advantages that the sheet piles in composite materials can offer. To build data that attests to the efficiency of its performances accessible to all sector professionals, it has carried out an important study in collaboration with IUAV University of Venice. This shows all the performance qualities of fiberglass pultruded sheet piles, after testing.

One of the advantages that our research adequately highlighted is a lower weight of fiberglass sheet piles compared to steel: they have a sealing capacity comparable to steel up to 12 metres deep, but they weigh five times less. From this data derives the observation that the use of pultruded sheet piles contributes to a reduction in construction site transport and handling costs.

Composite materials with fibreglass or carbon fibre are anti-corrosion and anti-rust: pultruded sheet piles can be used without suffering marine or non-marine water damage or contact with aggressive liquids

Catalogs

No catalogs are available for this product.

See all of Saimex Srl‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.