- Production Machines

- Other Manufacturing Equipment

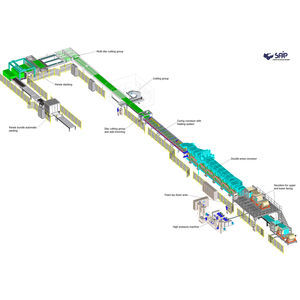

- Sandwich panel production line

- SAIP Advanced Polyurethane Equipment

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Foam panel production line CONTITECH RFsandwich panelinsulation panelPUR sandwich panel

Add to favorites

Compare this product

Characteristics

- Finished product

- for foam panels, sandwich panel, insulation panel, PUR sandwich panel, EPS/mineral wool sandwich panel, EPS sandwich panel, PUR isolation panel

- Other characteristics

- automated, continuous, double, linear, gluing

- Sector

- construction, for assembly lines, for the automotive industry, for the metallurgical industry

Description

SAIP offers complete solutions for the production of sandwich panels for roofs and walls, industrial or architectural, with PUR, PIR and rock wool cores, as well as complete solutions for the production of sectional panels for industrial and residential doors and gates. The continuous panel production method involves dosing the polyurethane reactive mixture between two coatings running in parallel on a conveyor belt. The reaction and curing of the polyurethane mixture takes place inside a moving press. The production speed varies according to the curing time of the foaming mixture, the thickness of the panels, and the minimum shear length.

storage and handling systems for chemicals

sheet metal forming section

high-pressure foaming machines, from 2 up to 8 components and more, which can also be used with new generations of blowing agents

continuous motion press with lengths from 12 to 42 meters

cutting unit, band saw and system disc

panel handling section including stacking, curing and packaging equipment

special sections dedicated to mineral wool and rock wool panel production and glue dispensing.

Catalogs

No catalogs are available for this product.

See all of SAIP Advanced Polyurethane Equipment‘s catalogsOther SAIP Advanced Polyurethane Equipment products

SANDWICH PANEL LINES

Related Searches

- Production machine

- Automatic making machine

- Pipe making machine

- Continuous production machine

- Panel making machine

- Construction making machine

- Flexible production machine

- Sheet metal production line

- Assembly line production line

- Double making machine

- Production line for the automotive industry

- Sandwich panel production line

- Linear production line

- Insulation panel production line

- Rotary production line

- Foam panel production line

- Discontinuous production line

- Gluing production line

- Production line for the metallurgical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.