- Production Machines

- Other Manufacturing Equipment

- Sheet metal production line

- SAIP Advanced Polyurethane Equipment

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

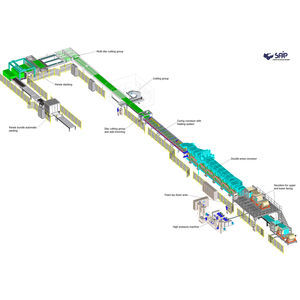

Panel production line DITECHsheet metalfor foam panelsdiscontinuous

Add to favorites

Compare this product

Characteristics

- Finished product

- sheet metal, for foam panels, panel

- Other characteristics

- flexible, discontinuous, gluing, for dispensers

- Sector

- for assembly lines

Description

DITECH is the SAIP technology that designs and builds complete lines for the production of panels with discontinuous method. The “discontinuous” process is used for the production of rigid surface panels, or flexible composite with a rigid polyurethane foam core, in those cases which require a particular design and limited production volumes. SAIP designs and produces multiple types of production lines, providing various solutions for the dosage of the foam according to the panel design, the production method and the efficiency required.

DITECH systems are entirely designed and manufactured according to specific customer requirements. DITECH technology offers turn-key solutions for different applications:

lines for the discontinuous production of architectural panels in hard surface with polyurethane core

implementation of existing lines using pentane as a blowing agent

storage systems, and management of chemical products

equipment for storage and management of chemical products

auxiliary equipment and lots more

The discontinuous production method consists in the polyurethane foam mixture pouring or injection into the cavity between two facings within the platens of a standing press.

Dosing is made by a low or high pressure two components foam dispensing machine, which is either especially designed according to the used foaming method or supplied as standard equipment. In order to have the best result, the foam distribution and its density on the whole surface should be homogeneous. To avoid air traps or overlaps of foam the pouring methods are very important.

Catalogs

CEDEPA

5 Pages

Other SAIP Advanced Polyurethane Equipment products

SANDWICH PANEL LINES

Related Searches

- Production machine

- Automatic making machine

- Pipe making machine

- Continuous production machine

- Panel making machine

- Construction making machine

- Flexible production machine

- Sheet metal production line

- Assembly line production line

- Double making machine

- Production line for the automotive industry

- Sandwich panel production line

- Linear production line

- Insulation panel production line

- Rotary production line

- Foam panel production line

- Discontinuous production line

- Gluing production line

- Production line for the metallurgical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.